Introduction to the operating principle of the wire twisting machine

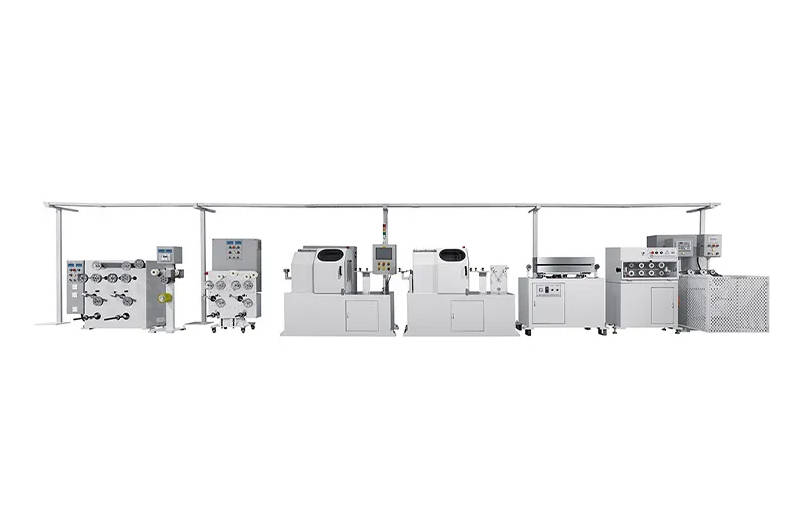

The application range of the wire twisting machine is very wide. In addition to the wire twisting machine, or the automatic wire twisting machine, the fully automatic wire twisting machine, the general automatic wire twisting machine can wind coils of different sizes, such as ring coils and square coils. These two are common. Their winding methods are mainly different in settings. Each type of coil must be set with appropriate basic parameters. In addition, the bearing capacity, wire passing technology, etc. must also be adjusted in time to make the wound coil meet the production process requirements and have a unique appearance.

When winding thin strip coils, the wire twisting machine generally adopts two wiring methods: random wiring and forced wiring. Both of these methods have their own advantages. Random wiring relies on the surface tension coefficient of the wire and the swing of the shaking wheel or pendulum to arrange the wire. The distance between the guide wheel and the coil frame is far. As long as it is adjusted properly, each turn of wire can be tightly wound, and the wound coil can fully achieve the desired effect of “mirror glass”, but it is very difficult to adjust, mainly because the control volume of the industrial equipment industry is too much; forced wiring uses the simultaneous movement of the winding machine spindle and the wire arrangement shaft, so that each turn is a certain distance, generally the distance of one cable diameter of the servo motor. In today’s development of electronic component CNC technology, it is not difficult to carry out. You only need to set the basic winding parameters in advance, and you can wind the wire without too much adjustment. However, according to everyone’s continuous experiments, the forced wiring method is very difficult to use for rapid winding of coils within 0.1mm, and often random winding occurs.

Dongguan twisting machine manufacturers need to first analyze the problem based on the situation. For example, take the twisting machine as an example to illustrate several common problems.

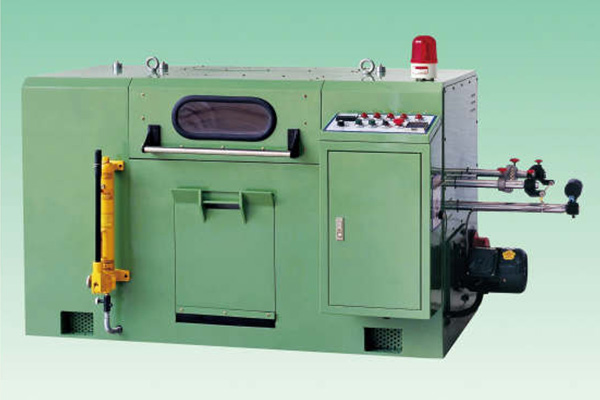

Wire twisting machine manufacturer

1.The wire is not neat. It is necessary to analyze according to the detailed situation whether the problem occurs during the normal production process, or the problem is formed after the product is changed and adjusted. The former is generally a system configuration problem. The latter is generally a setting problem. System configuration problems are generally caused by loose fixtures, loose fixing screws of the wiring mechanism, and poor lubrication of the wiring mechanism, which leads to overload of the AC servo motor and loss of step of the AC servo motor, resulting in uneven wiring.

2.The parking position of the machine tool spindle is not accurate. The inaccurate parking position of the machine tool spindle is generally caused by brake pad failure. For example, the brake pad is loose or the brake pad is damaged. It is also related to the setting of the brake pad time. If the brake pad time is too short, the parking position of the machine tool spindle will be strictly prohibited. Be sure to remove the brake pad or. Adjust the brake pad time.

3.The number of winding coils is strictly prohibited. If the wire winding machine produces a count prohibition, it is generally due to the system configuration problem of the sensor or controller. If such a thing occurs, the stranding machine cannot work. Generally, the Dongguan stranding machine manufacturer is notified for repair.