In the rapidly evolving sectors of telecommunications and power transmission, the demand for high-performance cables—specifically Optical Ground Wire (OPGW) and hybrid fiber optic cables—has reached unprecedented levels. These cables represent the lifeline of modern infrastructure, carrying both high-voltage electricity and high-speed data. However, manufacturing them presents a unique engineering challenge: the materials involved are incredibly fragile, expensive, and sensitive to mechanical stress.

For cable manufacturers, selecting the right stranding equipment is not merely a matter of production speed; it is a matter of product viability. While high-speed tubular stranders dominate the production of standard copper and aluminum conductors, they are often unsuitable for optical cables. This is where the Planetary Cable Machine (also known as a Planetary Strander or Planetary Cage Type Twisting Machine) becomes indispensable.

This comprehensive guide explores the engineering principles behind planetary technology, explaining why it is the only viable solution for OPGW and fiber optic armoring, and how it ensures zero-defect production in a high-stakes industry.

I. The Unique Challenge of OPGW and Fiber Optic Manufacturing

To understand the necessity of a planetary machine, one must first understand the anatomy of the product. OPGW is a dual-functioning cable. It acts as a ground wire to protect overhead transmission lines from lightning strikes while simultaneously housing optical fibers within a central tube (usually stainless steel or aluminum) for data transmission.

The manufacturing process involves stranding layers of Aluminum Clad Steel (ACS) or Aluminum Alloy wires around this central optical unit. The challenge lies in the vulnerability of the optical fibers.

Fragility: Optical fibers are glass strands. Even microscopic cracks or stress fractures can lead to immediate failure or reduced lifespan.

Signal Attenuation: If the cable is twisted or stretched during production, the fibers inside experience “micro-bending,” which causes significant signal loss (attenuation).

Cost of Failure: OPGW is expensive to produce. A single defect caused by improper machine tension or torsion can result in the scrapping of kilometers of cable, costing manufacturers thousands of dollars.

For these reasons, the primary requirement for OPGW machinery is not just speed, but absolute stability, precision tension control, and, most importantly, zero torsion. This is a requirement that only a high-quality Planetary Cable Machine can fulfill.

II. The Science of “Back-Twist”: Why Zero Torsion Matters

The defining feature of a planetary strander is its ability to provide 100% back-twist (also known as detorsion). To understand why this is critical, we must look at the physics of stranding.

In a standard “rigid” or “tubular” stranding machine, the payoff bobbin is fixed to the rotating cage. As the cage rotates around the center, the wire is twisted 360 degrees on its own axis for every single revolution of the machine. For a solid copper wire, this torsional stress is acceptable. For a tube containing optical fibers, this torsion is catastrophic. It would twist the internal fibers, causing them to snap or degrade.

A Planetary Cable Machine utilizes a unique mechanical design where the payoff cradles (holding the bobbins) remain floating or horizontal relative to the ground, even as the main cage rotates around the central axis.

This is achieved through a specialized gearing system or a chain-reaction mechanism at the rear of the cage. As the cage turns, the back-twist gear rotates the cradle in the exact opposite direction of the cage’s rotation.

Planetary Cable Machines are essential for fiber optics because they employ a 100% back-twist mechanism. This ensures that the individual wire or optical tube is laid into the helix without rotating on its own axis, resulting in a torsion-free cable structure that preserves the integrity of delicate internal fibers.

By eliminating torsional stress, the planetary machine ensures that the stainless steel tube housing the fibers retains its circular shape and that the fibers inside remain loose and stress-free (“floating”) within the gel, maintaining optimal signal transmission properties.

III. Precision Tension Control: Protecting the Core

In OPGW production, the central optical unit is the “heart” of the cable. If the outer wires are stranded with inconsistent tension, two major issues occur:

- Crushing: If the tension is too high, the outer wires will compress the central optical tube, potentially cracking the fibers.

- Bird-caging: If the tension is too low or uneven, the wires will not sit flush against the core, creating gaps (bird-cages) that compromise the cable’s electrical conductivity and mechanical strength.

Planetary Cable Machines designed for OPGW—such as the Heavy Weight Type Planetary Cage Type Twisting Machines manufactured by industry leaders like Qingfeng—incorporate advanced tension control systems to mitigate these risks.

Types of Tension Control in Planetary Machines

| Tension System | Mechanism | Application Suitability | Pros/Cons |

| Mechanical Friction | Uses brake pads/belts on the bobbin pintle. | Standard steel ropes; simple armoring. | Pro: Low cost. Con: Tension fluctuates as the bobbin empties; requires manual adjustment. Not recommended for high-end OPGW. |

| Hysteretic (Magnetic) Brakes | Uses magnetic fields to create contactless resistance. | High-quality OPGW & Fiber Optics. | Pro: Extremely constant tension; no wear and tear; precise control. Con: Higher initial investment. |

| Motorized/Servo Tension | Each bobbin is driven by an individual motor. | Ultra-sensitive applications (e.g., Subsea cables). | Pro: Best possible control with active feedback. Con: Most expensive; complex maintenance. |

For OPGW manufacturers, Hysteretic or Pneumatic tension capability is often the standard requirement. These systems ensure that the tension remains constant from the moment the bobbin is full (heavy) to when it is nearly empty (light). This consistency allows the outer Aluminum Clad Steel (ACS) wires to form a perfect, tight helix around the optical core without exerting crushing force.

IV. Handling Hybrid Materials and Armoring

One of the distinct advantages of the Planetary Cage Stranding Machine is its versatility. OPGW is a hybrid product, often requiring the machine to strand different materials with different physical properties simultaneously.

A typical OPGW construction might involve:

- Layer 1: A stainless steel tube with optical fibers.

- Layer 2: 6 wires of Aluminum Clad Steel (ACS).

- Layer 3: 12 wires of Aluminum Alloy (AA).

Because ACS and AA wires have different tensile strengths and moduli of elasticity, they behave differently during the stranding process. A planetary machine allows for the precise adjustment of each payoff position.

Furthermore, Planetary machines are the industry standard for Steel Wire Armoring (SWA). When producing heavy-duty fiber optic cables (such as submarine cables or direct-buried cables), a layer of galvanized steel wire must be applied for mechanical protection.

Why Planetary for Armoring?

Rigid or Tubular machines generate immense centrifugal force. If you attempt to armor a cable with heavy steel wires on a high-speed tubular machine, the centrifugal force creates an outward pull on the wires (“ballooning”). This makes it difficult to control the precise placement of the armor wires.

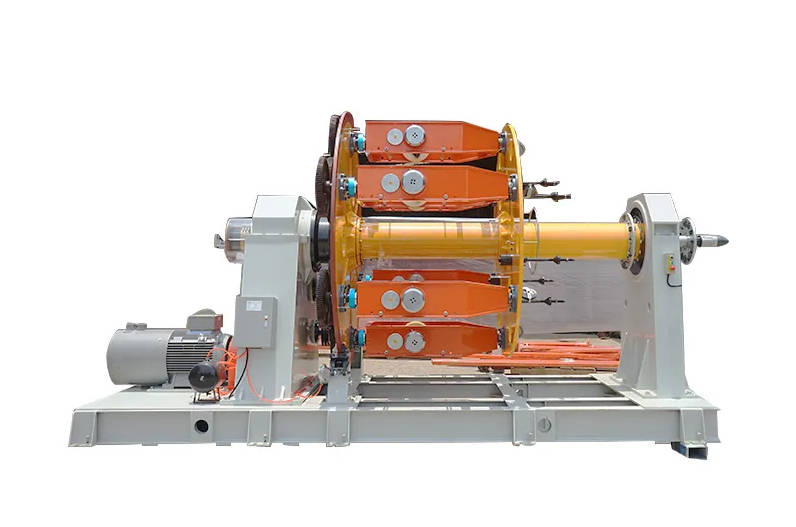

Planetary machines operate at lower rotational speeds with minimal centrifugal force. This allows the heavy steel wires to be guided gently and accurately into the stranding point. This is particularly vital for the “Heavy Weight Type” planetary machines (e.g., Φ630 or Φ800 models), which are specifically designed to handle the heavy load of steel wire bobbins while maintaining the delicate touch required for the optical core.

V. Planetary Strander vs. Tubular Strander: A Comparative Analysis

A common question from facility managers is: “Tubular stranders are faster. Why can’t I use them for OPGW?”

While it is true that tubular machines offer higher RPM (Revolutions Per Minute), the trade-off in quality makes them unsuitable for the optical layers of OPGW. Below is a detailed comparison of why the Planetary design wins for this specific application.

Comparison Table: Planetary vs. Tubular Stranding

| Feature | Planetary Cable Machine | Tubular (High-Speed) Strander |

| Back-Twist Capability | 100% Constant Back-Twist. | Usually 0% (No back-twist) or partial. |

| Torsional Stress | Zero Torsion. Ideal for optical fibers. | High Torsion. Twists the wire on its axis. |

| Centrifugal Force | Low. Gentle handling of materials. | High. Can damage delicate insulation or cores. |

| Wire Path | Gentle, straight path from cradle to die. | Complex path; wire threads through the tube body. |

| Number of Wires | Can handle many wires (cages of 6, 12, 18, 24, 30+). | Typically limited to 6 or 12 per tube section. |

| Speed | Low to Medium (e.g., 40-150 RPM). | High (e.g., 400-800 RPM). |

| Best Application | OPGW, Fiber Optics, Subsea Cables, Robotics Cables. | Standard Copper/Aluminum conductors, Steel Ropes. |

In summary: While Tubular Stranders offer higher production speeds, they impart torsional stress that damages optical fibers. Planetary Cable Machines are superior for OPGW manufacturing because their low centrifugal force and 100% back-twist capability prevent signal attenuation and structural damage during the stranding process.

For manufacturers aiming to produce certified, utility-grade OPGW, the Planetary machine is not an option—it is a technical necessity.

VI. Key Features to Look for When Buying a Planetary Machine

If you are in the market for a Planetary Cage Type Twisting Machine, specifically for OPGW or high-end cable production, simply asking for “a planetary machine” is not enough. The build quality varies significantly between manufacturers.

Based on industry best practices and the standards set by leading manufacturers like Qingfeng, here are the critical features you must evaluate:

1. Cage Stability and “Under-Roller” Support

The “cage” is the massive rotating part of the machine. For large machines (e.g., 1250 Planetary Cage), the weight of the bobbins is immense. Look for machines that utilize a thick-walled seamless steel pipe for the main shaft or a design that uses large under-rollers to support the cage weight.

Why? If the cage sags or vibrates, it causes tension spikes in the wire. A stable cage ensures smooth operation and longer bearing life.

2. Intelligent Wire Break Detection

In OPGW production, you cannot afford to run the machine if a single wire breaks. The machine must stop instantly.

Modern planetary machines utilize non-contact sensors or mechanical triggers at the stranding die.

Crucial Feature: The braking system must be powerful enough to stop a fully loaded cage within seconds to prevent the broken wire end from being buried in the cable, yet controlled enough not to snap the other wires.

3. Loading Efficiency (Motorized/Side Loading)

The biggest downside of planetary machines is the loading time. Because bobbins are loaded inside a cage, it takes longer than a tubular machine.

The Solution: Look for machines equipped with auto-side loading or separate motorized loading devices. This can reduce changeover time by 40%, significantly boosting your daily output.

4. Customization for “Light” vs. “Heavy” Duty

Not all planetary machines are built the same.

Light Type Planetary Machines: (e.g., Φ400 or Φ500) are ideal for stranding the initial optical units or smaller control cables. They offer higher speeds and finer tension control.

Heavy Weight Type Machines: (e.g., Φ630, Φ800) are required for the final armoring layers of OPGW or submarine cables. These machines must handle the immense torque required to form stiff steel wires into a helix.

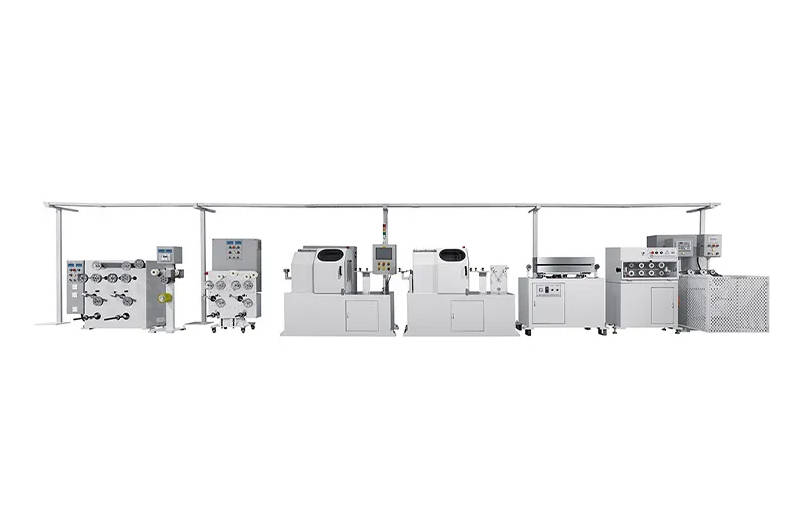

Manufacturers like Qingfeng offer the advantage of Cable Plant Design services, helping you choose the right combination of Light and Heavy machines to balance your production line flow.

VII. Maintenance and Long-Term Durability

Investing in a Planetary Cable Machine is a significant capital expenditure. To ensure a Return on Investment (ROI), buyers must consider the machine’s longevity and ease of maintenance.

The complexity of the planetary gear/chain system means there are many moving parts.

Lubrication: High-end machines feature centralized oil lubrication systems that automatically grease the gears and bearings. This reduces the risk of human error and seizing.

Spare Parts Availability: This is often an overlooked factor. A machine is only as good as its uptime. As noted in the service offerings of top-tier suppliers, having a partner who guarantees “Cheap Spare Parts” and maintains a “20-year inventory” (like tension controllers and gears) is vital. It ensures that your production line doesn’t sit idle for weeks waiting for a custom gear to be machined.

Regular maintenance checks on the back-twist timing belts or gears are essential. If the back-twist mechanism drifts, the machine effectively becomes a rigid strander, risking the quality of the optical cable.

VIII. Conclusion

In the world of wire and cable manufacturing, the Planetary Cable Machine stands as the guardian of quality for the most sensitive and critical cables. While it may not match the raw speed of tubular stranders, its ability to deliver zero-torsion stranding, precise tension control, and low-stress handling makes it the undisputed choice for OPGW, fiber optics, and submarine cable armoring.

For manufacturers, the choice is clear: to compete in the high-value market of optical ground wires, you must invest in machinery that respects the fragility of the fiber.

Ready to Upgrade Your OPGW Production Line?

Whether you need a Heavy Weight Type Planetary Cage for robust steel armoring or a specialized High Frequency Cable Non-back Twisted solution, choosing the right partner is key.

Qingfeng Electrical Machinery specializes in custom-designed Planetary Cable Machines tailored to your specific production needs. With a focus on robust engineering, comprehensive plant design, and long-term spare parts support, we help you build cables that connect the world.

Contact us today to discuss your cable specification and get a customized technical proposal for your planetary stranding line.