In the wire and cable manufacturing industry, facility layout and machinery configuration are critical decisions that impact capital expenditure, production efficiency, and product quality. One of the most fundamental questions factory planners face is regarding the orientation of the production line: Should you invest in a standard Horizontal Extrusion Line, or does your product require a Vertical Extrusion solution?

For 90% of standard cable applications—from PVC building wires to LAN cables—the horizontal line is the industry workhorse. However, as manufacturers push the boundaries into Extra-High Voltage (EHV) power cables or specialized materials like Liquid Silicone Rubber (LSR), the physics of gravity becomes a formidable enemy.

This comprehensive guide analyzes the engineering differences between Vertical (VCV) and Horizontal (Standard & CCV) Wire Extrusion Lines. We will help you navigate the trade-offs between factory height, land length, and gravitational forces to ensure you select the right machine for your specific cable application.

I. Introduction: Gravity, Viscosity, and Factory Footprint

At its core, the debate between vertical and horizontal extrusion is not about personal preference; it is about physics. When molten plastic or rubber exits the extruder crosshead, it is in a semi-liquid state. Until it cools or cures (vulcanizes) into a solid, it is susceptible to two main forces:

- Viscosity/Surface Tension: The material’s internal resistance to flow.

- Gravity: The force pulling the material downward.

If the insulation layer is thin and the cooling is fast, gravity has little time to act. However, if the insulation is thick (heavy) or the material is very fluid (like silicone), gravity will pull the material down before it sets. This results in an oval-shaped cable or an eccentric conductor (off-center).

The choice between Vertical and Horizontal Wire Extrusion Lines is primarily determined by the wall thickness of the cable insulation and the viscosity of the polymer. Horizontal lines are cost-effective for standard applications, while Vertical lines are essential for heavy-wall High-Voltage cables and low-viscosity materials to combat gravitational sag.

II. Horizontal Extrusion Lines: The Industry Workhorse

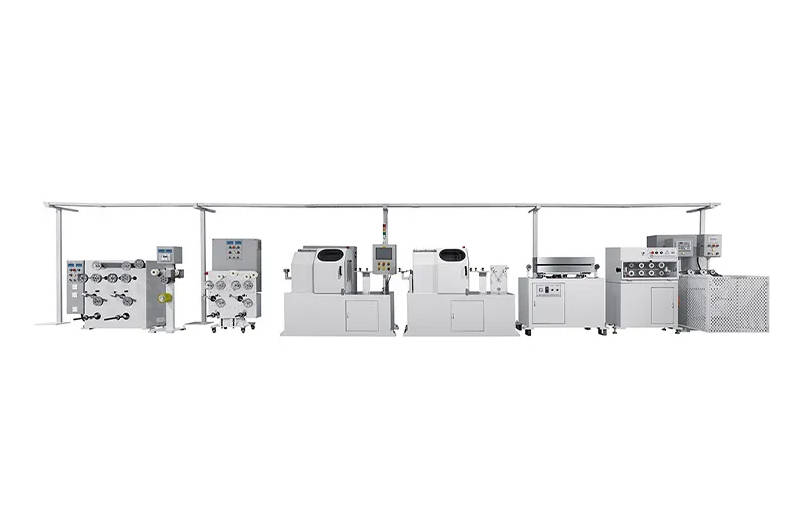

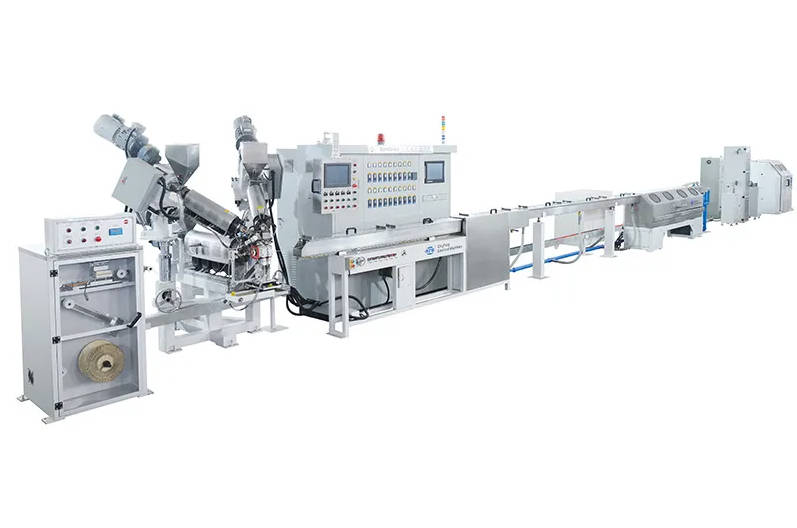

The Horizontal Wire Extrusion Line is the most common configuration found in cable factories worldwide. In this setup, the Payoff, Pre-heater, Extruder, Cooling Trough, Capstan, and Take-up are arranged in a straight line on the factory floor.

1. Standard Horizontal Lines (Thermoplastics)

For materials that cool physically (like PVC, PE, PP, Nylon, and TPU), the horizontal line is the undisputed champion.

- Mechanism: The wire moves horizontally through the crosshead. The molten plastic is applied, and the wire immediately enters a water trough.

- Application: Building wires, Automotive wires, Data cables (Cat6, USB, HDMI), and Low-Voltage power cables.

- Gravity Management: Because the insulation is relatively thin (usually <3mm) and the line speed is high, the plastic “freezes” in the water trough before gravity can deform it.

2. The CCV Line (Catenary Continuous Vulcanization)

When producing Medium and High Voltage cables (11kV – 132kV) using XLPE (Cross-linked Polyethylene), the cable cannot be cooled in water immediately; it must be cured in a hot nitrogen tube. Because the insulation is thicker, gravity becomes an issue.

To solve this without building a tower, engineers developed the CCV Line.

- The Catenary Curve: Although the extruder is on the ground, the curing tube (often 100m+ long) is not perfectly flat. It is built with a calculated downward slope (a catenary curve).

- How it Works: The tension on the cable is adjusted so that the cable hangs in the center of the tube, not touching the walls. The cable rotates slightly to help distribute the gravitational pull.

Pros and Cons of Horizontal/CCV Lines

| Feature | Horizontal / CCV Lines |

| Capital Cost | Lower. No need for specialized skyscrapers or deep pits. |

| Maintenance | Easier. All components are accessible from the ground or low platforms. |

| Line Speed | Higher. Generally faster for smaller cross-sections. |

| Limitations | Eccentricity (Pear Shape): On very thick cables (e.g., >20mm insulation), gravity pulls the melt down, creating a pear-shaped insulation. |

| Footprint | Large Length: Requires a very long factory floor (150m – 200m). |

III. Vertical Extrusion Lines: The Specialist Solutions

Vertical extrusion is not a “better” version of horizontal; it is a specialized solution for specific engineering challenges. There are three distinct contexts where you would choose a Vertical setup.

Context 1: The VCV Line (Vertical Continuous Vulcanization)

This is the “Formula 1” of cable manufacturing, designed for Extra-High Voltage (EHV) cables (220kV – 500kV+) and massive Subsea cables.

- The Tower: The extruder is mounted at the top of a massive tower (often 50m to 100m high). The cable is extruded downwards towards the ground.

- The Physics: Because the cable travels vertically, gravity acts parallel to the conductor axis, not perpendicular to it. There is no force pulling the insulation to the “bottom” side because there is no bottom side relative to the cable’s cross-section.

- The Result: Perfect concentricity. The insulation remains perfectly round regardless of how thick it is or how long it takes to cure.

Context 2: Vertical Silicone Extrusion

Liquid Silicone Rubber (LSR) is unique. Before curing, it acts like a paste or liquid.

- The Problem: If you extrude silicone horizontally, it will flatten into a ribbon shape instantly before it enters the oven.

- The Solution: Vertical Silicone Lines extrude the wire downwards (or sometimes upwards) into a vertical Infrared (IR) Shock Oven. The vertical orientation holds the shape until the heat “locks” the silicone geometry.

- Application: Medical tubes, high-temperature fiberglass sleeving, flexible HV joint cables.

Context 3: Vertical Auxiliary Extruders (Co-Extrusion)

This is a space-saving hack for standard factories.

- Scenario: You have a horizontal line, and you want to add a color stripe (skin) to the wire, but you don’t have floor space to place another extruder next to the main one.

- Solution: A Vertical Extruder is mounted directly on top of the main extruder’s crosshead. It feeds the stripe material from above. This saves valuable floor space and allows for easy retrofitting of existing lines.

IV. Comparative Analysis: Key Decision Factors

When deciding between these configurations, you must evaluate three critical factors: Product Specification, Infrastructure, and Budget.

Factor 1: The “Sag” Limit (Insulation Thickness)

The most scientific way to choose is to look at the “Sag Limit.”

- Horizontal (CCV): Can effectively handle conductor cross-sections up to 1000mm² and insulation thicknesses up to roughly 25mm – 30mm. Beyond this, the weight of the insulation becomes too great for the surface tension to hold, and the cable becomes “pear-shaped.”

- Vertical (VCV): Is required for conductors >1000mm² (up to 3500mm²) and insulation thicknesses >30mm. In VCV, there is theoretically no limit to thickness regarding concentricity.

Google Snippet: The primary difference between CCV (Horizontal) and VCV (Vertical) lines lies in gravity management. CCV lines use a catenary curve to support the cable but are limited by insulation weight, making them suitable for up to 132kV. VCV lines extrude vertically, eliminating gravitational sag entirely, making them the only viable option for Extra-High Voltage cables (220kV – 500kV) with heavy insulation walls.

Factor 2: Infrastructure (Height vs. Length)

- Horizontal Line Requirements:

- Length: needs 100m – 200m of continuous length.

- Height: Standard factory ceiling (6m – 8m).

- Real Estate Cost: Usually cheaper in rural industrial zones.

- Vertical Line Requirements:

- Length: Very compact footprint (small land area).

- Height: Requires a tower 50m – 120m tall.

- Construction Cost: Extremely high. Building a tower requires specialized foundations, wind load calculations, and elevators.

Factor 3: Operational Efficiency (OPEX)

- Changeover: Horizontal lines are faster to change over. Operators can walk to the head. On a VCV tower, operators must take elevators to different levels to clean the head or adjust parameters.

- Energy: VCV towers often use gravity to help transport the cable, requiring slightly less capstan tension, but the elevators and HVAC systems for the tower add to energy costs.

Comparison Table: Vertical vs. Horizontal Selection

| Feature | Standard Horizontal | CCV Line (Catenary) | VCV Line (Vertical) | Vertical Silicone Line |

| Primary Use | PVC/PE Building Wire, Data Cable | MV/HV Power Cable (11-132kV) | EHV Power Cable (220-500kV) | Medical/High-Temp Wire |

| Material State | Melts quickly, cools fast | XLPE (Chemical Cure) | XLPE (Chemical Cure) | Paste/Liquid (Thermal Cure) |

| Main Advantage | Low Cost, High Speed | Good balance of cost/performance | Perfect Concentricity | Maintains shape of soft material |

| Main Disadvantage | Not for chemical curing | Sag limits max cable size | Extremely High Cost (Tower) | Slow production speed |

| Gravity Effect | Negligible | Managed by Tension/Rotation | Eliminated | Eliminated |

V. Case Studies: Which Line Fits Your Product?

To make this decision practical, let’s look at four distinct manufacturing scenarios.

Scenario A: The Mass Market Manufacturer

- Product: Housing wires (THHN), Control cables, Cat6 LAN cables.

- Material: PVC, LSZH, HDPE.

- Verdict:Horizontal Extrusion Line.

- Reasoning: The insulation is thin (<1mm). Cooling happens instantly in water. A vertical line would be a massive waste of money and would actually slow down production due to the complexity of vertical string-up.

Scenario B: The National Grid Supplier

- Product: 400kV Underground Transmission Cable.

- Material: Super-clean XLPE. Conductor: 2500mm² Copper (segmented).

- Verdict:Vertical (VCV) Line.

- Reasoning: A 2500mm² copper conductor is incredibly heavy. The XLPE insulation wall is over 30mm thick. If run on a horizontal line, the insulation would droop significantly. To meet IEC standards for EHV cables, a VCV tower is mandatory.

Scenario C: The Medical Device Specialist

- Product: Flexible Silicone Tubing and Silicone-insulated wiring.

- Material: Liquid Silicone Rubber (LSR).

- Verdict:Vertical Silicone Extrusion Line.

- Reasoning: The raw silicone has the consistency of toothpaste. A horizontal oven would result in a flat “tape” rather than a round tube. The vertical oven allows the silicone to cure into a perfect circle before it touches any pulley or belt.

Scenario D: The Space-Constrained Factory

- Product: PVC Earth wires with a Green/Yellow stripe.

- Constraint: The factory floor is full; no room to add a stripe extruder next to the main line.

- Verdict:Horizontal Main Line + Vertical Auxiliary Extruder.

- Reasoning: By mounting the small “Stripe” extruder vertically on top of the main crosshead (Piggyback style), the manufacturer adds capability without expanding the factory footprint.

VI. Buying Guide: Questions to Ask Your Manufacturer

If you are negotiating with Wire Extrusion Line suppliers, asking the right questions can save you from a costly mistake.

For Power Cable Lines (CCV vs. VCV):

- “What is the guaranteed eccentricity tolerance for a 1000mm² cable on your CCV line?”

- If they promise 100% concentricity on a horizontal line for huge cables, be skeptical. Ask for reference customers producing similar sizes.

- “Do you offer a ‘Top-Down’ or ‘Bottom-Up’ configuration for silicone?”

- Top-down is standard, but bottom-up is sometimes used for specific medical profiles.

For Space Optimization:

- “Can the co-extruder be mounted on a rotating column?”

- This allows the vertical auxiliary extruder to be moved out of the way easily when you are doing maintenance on the main screw.

- “What is the height requirement for the vertical co-extruder?”

- Ensure your factory ceiling clearance is sufficient to remove the screw from the vertical extruder for cleaning.

VII. Conclusion

The decision between a Vertical and a Horizontal Wire Extrusion Line is rarely a grey area—it is a decision dictated by the physical properties of your product.

- Choose Horizontal Lines for high-speed, cost-effective production of thermoplastics and standard power cables up to 132kV. It is the efficient choice for 90% of the market.

- Choose Vertical (VCV) Lines when you enter the elite tier of Extra-High Voltage manufacturing, where the battle against gravity defines the quality of the cable.

- Choose Vertical Silicone Lines when working with low-viscosity elastomers that demand shape retention during curing.

Understanding these distinctions ensures that your capital investment aligns with your production goals. Do not build a tower for a product that belongs on the ground, but do not expect a ground-level line to defy the laws of gravity for a 400kV cable.

Ready to Specify Your Line?

Whether you need a compact Vertical Co-Extruder to save space or a robust Horizontal Sheathing line for high output, the key is customization. Contact industry experts to simulate your cable production and determine the exact configuration that maximizes your ROI.