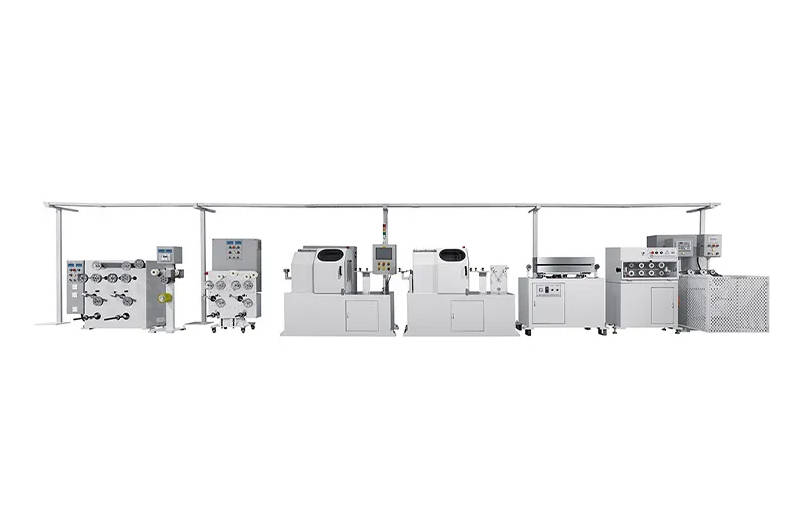

In the cable and wire rope manufacturing industry, choosing the right stranding equipment is a decision that impacts not only production speed but the fundamental structural integrity of the final product. For manufacturers dealing with high-specification cables—such as submarine power lines, Optical Ground Wire (OPGW), and umbilical cables—the debate often centers on two primary technologies: the Tubular Strander and the Planetary Stranding Machine.

While both machines serve the purpose of twisting individual wires into a stranded conductor or rope, their mechanical approach to “Stress Control” is diametrically opposed. This article provides a deep dive into the engineering differences between these two systems, helping technical buyers understand why planetary machines remain the gold standard for stress-sensitive applications.

1. Introduction: The Cable Quality Paradox

In modern manufacturing, there is a constant tension between output volume and structural precision. The Tubular Strander is the “sprinter” of the industry, designed for maximum RPM and high-speed throughput. In contrast, the Planetary Machine is the “precisionist,” designed to manage the internal physics of the wire with extreme care.

For end-users, the “stress” within a cable isn’t just a theoretical concern. It manifests as kinking, “bird-caging,” and premature fatigue failure. The core difference between a tubular strander and a planetary machine is how they handle torsional stress: a tubular strander induces a full twist into each wire per revolution, whereas a planetary machine utilizes a back-twist mechanism to neutralize that stress entirely.

2. Mechanical Foundations: How They Move

To understand stress control, we must first look at the mechanical geometry of both machines.

Tubular Strander Logic

A tubular strander consists of a long, high-speed rotating tube supported by several bearings. The bobbins are placed inside the tube in a straight line. As the tube rotates, the wire is guided along the inner wall of the tube toward the stranding die.

- The Path: The wire follows a “straight-line” path relative to the machine’s axis, but it is forced to rotate with the tube.

- The Mechanics: There is no mechanism to rotate the bobbins independently. Therefore, the bobbin remains fixed relative to the tube’s rotation.

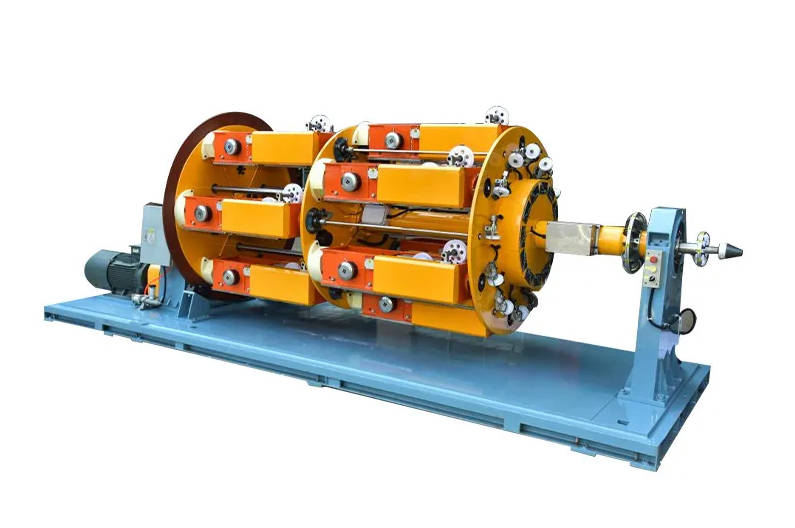

Planetary Machine Logic

A planetary machine features a large rotating cage that carries several bobbin cradles. These cradles are not fixed; they are connected to a planetary gear system.

- The Orbiting Path: As the main cage rotates, the bobbins “orbit” the central axis like planets around a sun.

- The Neutral Axis: The defining characteristic is that the bobbins can be rotated in the opposite direction of the cage. This ensures the wire is pulled off the spool without being twisted around its own longitudinal axis.

3. Torsional Stress: The Silent Quality Killer

Torsional stress, or “residual torsion,” is the internal torque trapped within a wire after it has been stranded.

The Tubular Twist

In a tubular machine, because the bobbin is fixed within the rotating tube, the wire undergoes one complete 360-degree twist for every lay length of the cable.

- The Result: The wire is under constant elastic (and sometimes plastic) deformation.

- The Problem: When the finished cable is cut, this stored energy wants to release. This causes the individual wires to “flare” or “unravel.” In severe cases, it leads to bird-caging, where the outer layers of wire pop up and separate from the core.

The Planetary Solution (Back-Twist)

Planetary machines eliminate torsional stress by employing a 100% back-twist mechanism, where the bobbin cradles rotate 360 degrees in the opposite direction for every full revolution of the machine cage.

By canceling out the rotation, the wire is laid into the cable in a “neutral” state. It is bent into a helix, but it is never twisted. This results in a “dead” cable—a product that lies perfectly flat when unspooled and shows zero tendency to kink or twist during installation.

4. Comparative Analysis: Technical Performance

For procurement managers, the choice often comes down to the following technical metrics:

Comparison Table: Tubular vs. Planetary

| Feature | Tubular Strander | Planetary Machine |

| Primary Advantage | High Production Speed | Superior Stress Control |

| Back-Twist Capability | None (0%) | 100% (or Adjustable) |

| Torsional Stress | High (1 twist/lay) | Zero / Neutral |

| Max RPM (Typical) | 500 – 1000+ RPM | 50 – 150 RPM |

| Material Handling | Robust (Copper, Steel) | Sensitive (OPGW, ACS, Fiber) |

| Cable “Deadness” | Requires Post-Forming | Naturally “Dead” |

| Maintenance Profile | Simple (Tube Bearings) | Complex (Planetary Gears) |

| Typical Product | Standard Electrical Wire | Submarine / High-Voltage |

Centrifugal Force Impacts

In a tubular strander, the wire is subject to intense centrifugal force as it is flung against the inner wall of the tube at high speeds. This can cause surface abrasion on delicate coatings. In a planetary machine, the wire path is more controlled, and the lower RPM significantly reduces centrifugal stress on the wire’s surface and the bobbin itself.

5. Why Planetary Machines are Non-Negotiable for High-Spec Cables

For certain industries, using a tubular machine is not just sub-optimal—it is often technically impossible or prohibited by international standards.

OPGW (Optical Ground Wire)

Optical Ground Wire contains fragile glass fibers housed in aluminum or steel tubes. Planetary machines are essential for OPGW manufacturing because any torsional stress applied during the stranding of the outer aluminum-clad steel wires could be transferred to the central tube, causing micro-bends in the fiber and significant signal attenuation.

Submarine Umbilicals and Power Cables

Submarine cables must be laid on the ocean floor in lengths reaching hundreds of kilometers. If these cables have residual torsion, they will form “loops” or “kinks” as they are lowered into the water. A planetary machine ensures the cable is structurally balanced, which is a critical safety requirement for deep-sea deployment.

Large-Section Sector Conductors

When working with “sector-shaped” conductors (where the wire is not round but shaped like a pie slice), orientation is everything. A tubular machine would twist the sector, making it impossible to fit the segments together. The planetary machine’s back-twist allows each sector to remain in the perfect orientation to form a compact, circular conductor.

6. Addressing Common Procurement & Engineering Doubts

“Is the lower RPM worth the investment?”

This is the most frequent question from factory owners. While a planetary machine produces less cable per hour than a tubular machine, the Return on Investment (ROI) comes from:

- Reduced Scrap: Zero bird-caging means fewer rejected batches.

- Higher Margins: Specialty cables (OPGW, Submarine) command much higher prices than standard building wire.

- Customer Compliance: High-tier utility companies often specify “Planetary Stranded Only” in their tender documents.

Maintenance Realities

It is true that planetary gear systems are more complex than the simple bearings of a tubular strander. However, modern planetary machines feature oil-bath gearboxes and automated lubrication systems that have pushed maintenance intervals to several thousand hours. The “complexity” is a manageable trade-off for the quality achieved.

Flexibility: The “Locked Cradle” Mode

Modern planetary machines are versatile. If a project does not require back-twist, the cradles can be “locked” in place. In this mode, the machine functions similarly to a rigid strander, allowing the factory to handle a wider variety of contracts with a single piece of equipment.

7. Operational Factors Affecting Stress Control

Stress control isn’t just about the gears; it’s also about how the machine is operated.

Back-Twist Ratio Adjustments

While 100% back-twist is the standard, some materials have a “memory.” Engineers might set the machine to 105% or 95% back-twist to compensate for the material’s tendency to spring back. This level of fine-tuning is only possible on high-end planetary equipment.

Tension Consistency

Precise stress control in a planetary machine is facilitated by individual bobbin tensioning systems, often utilizing hysteresis brakes or AC servo motors to ensure that every wire in the layer is laid with identical tension. If tension is uneven, the cable will “corkscrew” even if back-twist is applied.

8. Conclusion: Which Machine Fits Your Factory?

The choice between a tubular and planetary machine depends entirely on your target market.

- Choose a Tubular Strander if your goal is the mass production of standard copper/aluminum conductors or simple steel wire ropes where speed is the primary driver of profitability.

- Choose a Planetary Machine if you are targeting the high-value energy and telecommunications sectors.

Ultimately, the planetary machine’s ability to provide absolute stress control is the key to producing cables that meet the world’s most stringent engineering standards. By neutralizing torsion and maintaining a neutral axis, the planetary strander ensures that the final product is stable, durable, and ready for the most demanding environments on Earth.