I. Introduction: The New Era of 224G Interconnects

The global demand for data bandwidth is exploding, driven by Artificial Intelligence (AI), Machine Learning (ML), and the expansion of hyperscale cloud data centers. As we transition from 112G per lane to the daunting 224G SerDes (Serializer/Deserializer) technology, the physical layer—specifically the high-speed copper interconnects—faces unprecedented challenges.

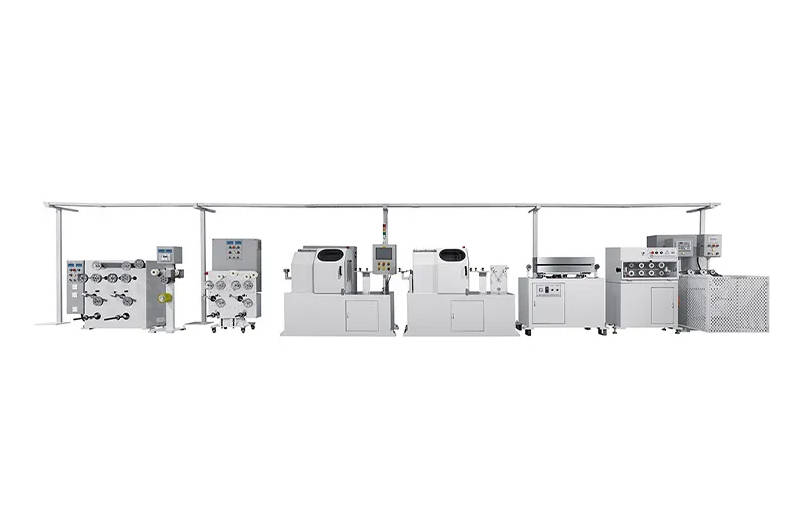

In this landscape, High-speed taping machines are critical for 224G interconnects because they provide the sub-micron precision in tape overlap and tension control necessary to minimize impedance discontinuities and signal attenuation in 800G and 1.6T networking cables. Without the advanced stability of modern taping equipment, manufacturing a cable that meets the strict IEEE 802.3dj or OIF-CEI-224G standards becomes a statistical impossibility.

For cable manufacturers and B2B buyers, understanding the synergy between mechanical precision and electrical performance is the key to maintaining a competitive edge in the 1.6T networking market.

II. The Technical Challenges of 224G Signal Integrity

As signal frequencies increase, the wavelength becomes shorter, making the signal significantly more sensitive to any physical imperfections in the cable structure. At 224G, even a microscopic gap in the shielding or a slight variation in the insulation thickness can lead to catastrophic signal failure.

1. Tightening Impedance Control

For 224G interconnects, the standard target impedance is usually 92 ohms or 100 ohms, but the tolerance window has shrunk dramatically. While 112G could tolerate a ±5 ohm variance, 224G often requires tolerances within ±2 ohms. The taping machine must apply the dielectric or shielding tape with such consistency that the physical diameter of the core remains uniform throughout the entire length of the spool.

2. Signal Loss and Attenuation

High-frequency signals travel on the “skin” of the conductor (the skin effect). Any unevenness in the taping process—such as inconsistent pressure or overlap—creates “traps” for the signal, leading to increased Insertion Loss (IL).

3. Skew and Phase Consistency

In Twinax (twinaxial) cables, the two internal conductors must be perfectly symmetrical. If the taping machine applies more tension to one side than the other, it creates a “time-of-flight” difference between the two signals, known as intra-pair skew. At 224G, even a few picoseconds of skew can collapse the signal eye diagram.

4. Comparison Table: 112G vs. 224G Cable Manufacturing Requirements

| Feature | 112G Requirements | 224G (800G/1.6T) Requirements | Impact of Taping Machine |

| Impedance Tolerance | ±3 to 5 Ohms | ±1 to 2 Ohms | Controls diameter consistency |

| Overlap Precision | ±5% | ±1% | Ensures shielding integrity |

| Tension Variation | ±10g | < ±2g | Prevents dielectric deformation |

| Frequency Range | Up to 28 GHz | Up to 56/112 GHz (Nyquist) | Minimizes resonance and loss |

| Material Usage | Standard PTFE / Mylar | Ultra-thin PTFE / Low-DK Films | Requires sensitive handling |

III. Why “High-Speed” Does Not Mean Sacrificing “Precision”

A common misconception among procurement officers is that “High-speed” taping machines are simply for volume and might compromise quality. In the context of 224G, speed and precision are actually inextricably linked through Dynamic Stability.

The Problem with Low-Speed Vibration

Old-generation machines running at low RPMs often suffer from mechanical resonances. These micro-vibrations translate into “periodic defects” in the cable. In the frequency domain, these defects manifest as “suck-outs” (Return Loss spikes) at specific frequencies.

Engineering for 224G Stability

Modern high-speed taping machines utilize high-precision balanced taping heads and carbon-fiber components to reach speeds of 2000-4000 RPM while maintaining zero vibration. This high rotational speed allows for a faster line speed (throughput) without sacrificing the Helix Angle—the angle at which the tape wraps around the conductor. A consistent helix angle is vital for ensuring the electrical field remains uniform.

IV. Core Features of a Professional 224G Taping Machine

If you are evaluating equipment for a 224G production line, these are the non-negotiable technical features:

1. Active Tension Control Systems

Unlike passive friction-based tensioners, an active system uses servo motors and dancer arms with closed-loop feedback. Active tension control in taping machines is essential for 224G cables to ensure that ultra-thin shielding tapes do not stretch or wrinkle, which would otherwise create localized impedance mismatches.

2. Precision Taping Heads with Centrifugal Compensation

At high speeds, centrifugal force can pull the tape away from the center. High-end machines feature “balanced” heads that compensate for this force, ensuring the tape always makes contact with the wire at the exact same pressure point.

3. Laser/CCD Real-Time Monitoring

Manual inspection is impossible at 224G speeds. Automated systems use high-speed cameras or laser micrometers to:

- Measure the outer diameter (OD) in real-time.

- Detect tape breakage or overlap errors.

- Log data for every meter of cable produced (essential for B2B traceability).

4. Advanced Material Handling

224G cables often use very thin, fragile materials like expanded PTFE (ePTFE) or specialized silver-plated copper tapes. The machine must have “soft-start” and “soft-stop” capabilities to prevent snapping these expensive raw materials.

V. Solving User Pain Points: The ROI of High-End Taping

Investing in a high-speed taping machine designed for 224G is a significant CAPEX decision. However, the Return on Investment (ROI) is found in three areas:

- Reduction in Scrap Rates: 224G raw materials (silver-plated copper and low-loss dielectrics) are incredibly expensive. A machine that reduces “out-of-spec” cable from 10% to 1% pays for itself within months.

- Market Readiness: 800G and 1.6T systems are the fastest-growing segments in the industry. Manufacturers who cannot prove their cable meets 224G SI (Signal Integrity) specs will be excluded from Tier-1 data center contracts.

- Throughput Efficiency: High-speed machines allow you to produce more kilometers of cable per shift, reducing the “cost-per-meter” despite the higher initial machine cost.

VI. FAQs: Addressing Common Buyer Concerns

Q1: Can I upgrade my existing 112G machines for 224G production?

Generally, no. While some components can be retrofitted, the mechanical tolerances and vibration damping required for 224G usually necessitate a machine designed from the ground up for high-frequency stability.

Q2: How does taping speed affect the skin effect?

The speed itself doesn’t change the physics of the skin effect, but the consistency of the tape at that speed does. Any irregularity in the shielding tape caused by mechanical instability will disrupt the signal path on the conductor’s surface, increasing attenuation.

Q3: What is the ideal overlap percentage for 224G shielding?

Most engineers aim for a 25% to 35% overlap. The critical factor is not just the percentage, but the constancy of that overlap. A fluctuation of even 2% can create a detectable signal reflection at 224G.

VII. Conclusion

The transition to 224G interconnects is a major leap in telecommunications history. It moves the industry from traditional cable manufacturing into the realm of high-precision microwave engineering.

As the heart of the cable assembly process, the high-speed taping machine determines whether a product is a high-performance 1.6T solution or merely expensive scrap metal. For manufacturers looking to lead in the AI era, investing in precision taping technology is the most critical step in ensuring signal integrity and production scalability.

Would you like a technical consultation on how our high-speed taping machines can optimize your 224G production line? Contact our engineering team today for a custom configuration.