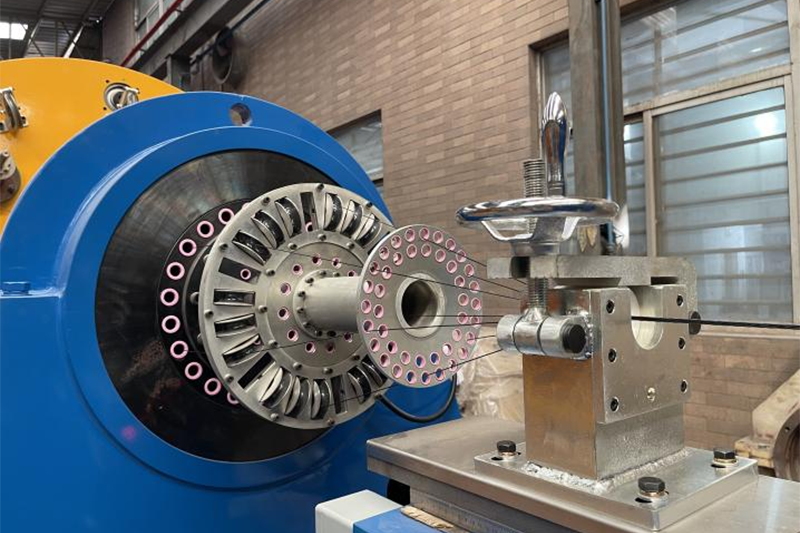

After the cage winch machine is installed and solidified, start installing the power wiring. After all installations are completed, please lubricate the rotating parts and start the motor. After running at low speed for 1 hour, please check whether the fasteners are loose, and tighten them if they are loose. After all inspections are completed, check the high-speed operation and no-load operation. Then, let’s understand the maintenance and care of the cage winch machine. The cage winch machine can twist 19 copper soft wires, remove one or two transmission parts, and produce 7 copper soft wires. It is also possible to return 12 winch wires separately.

Install the wire reel, pull the wire to the take-up reel, close the protective net, start the motor, gradually adjust the speed, check the tension of the elastic friction belt installed on the reel friction wheel, the friction belt tension is too large, the wire cannot be broken, the friction belt tension is too small, the wire of the wire roll is easy to flip after stopping, so before and during use, check the rotation of the wire roll and the condition after stopping.

After the winding coil is full, stop the main machine, rotate the transmission connection to the rising position, start the rise and twist down, take out the winding shaft, install the empty disc, and rise to the transmission connection position. During the assembly and disassembly of the whole board, be sure to pay attention to whether the assembly and disassembly position of the transmission connection part is aligned.

Every time you start or replace the wire drum of the cage winch, you must reset the speed regulator to zero to prevent the speed regulator from being damaged during linear motion. The main machine stops running but does not stop running or an accident occurs.

Maintenance and maintenance of the cage winch.

The cage winch is a frame structure. The main function of the cage winch is a rotating body. The main body will shake slightly due to the poor weight balance of the wire drum. When running the squirrel cage winch, please pay attention to the lubrication of the transmission parts of each part. Please add lubricating oil every 10 days of production to avoid wear of the rotating parts due to lack of lubricating oil.

Long-term use of the wire drum between the tension friction wheel and the bevel gear can cause damage to the rotating bearing. The damaged bearing can be replaced at any time.

Long-term use of friction transmission friction plates and friction plates of the cage winch will wear the friction plates. Please replace them in time. The friction disc is reprocessed, and the friction coefficient meets the requirements of friction and sliding, ensuring the normal operation of the disc and driving the winding shaft to rotate.

1.The inside and outside of the cage are clean, and each folding surface and lead screw, gear, frame, etc. are free of oil and scratches; each part does not leak oil, water, air, or air; clean up the chips and garbage.

2.In order to avoid the line of the steel bar rolling cage being affected, the steel bar rolling cage should be placed in a dry room and not in a humid environment. If it needs to be placed outdoors, it must be placed on a flat ground. In addition, in order to prevent the steel bar bending machine from getting wet, it must be covered with a cloth.

3.Parts that need to be lubricated regularly.

4.Please turn off the power and turn off the power switch when leaving the front rolling cage.

5.Please place the fuel lever of the machine in the idle position. If it is not set to the idle position, it will cause harm to the engine. Please place each joystick in the neutral position.

6.The operator of the auger must have skilled technology and be familiar with the performance of the drum cage. When abnormal conditions occur, they can be solved in time to avoid damage to the steel bar bending machine.

7.Before operation, the cage winch should be inspected to see if the parts of each station are within the normal working range. If there is any abnormality, it should be reported and handled in time.