What is the difference between cage-type stranding machines and frame-type stranding machines?

We have previously compared cage-type and frame-type stranding machines; today we shall examine their distinctions.

1. Production Processing Speed

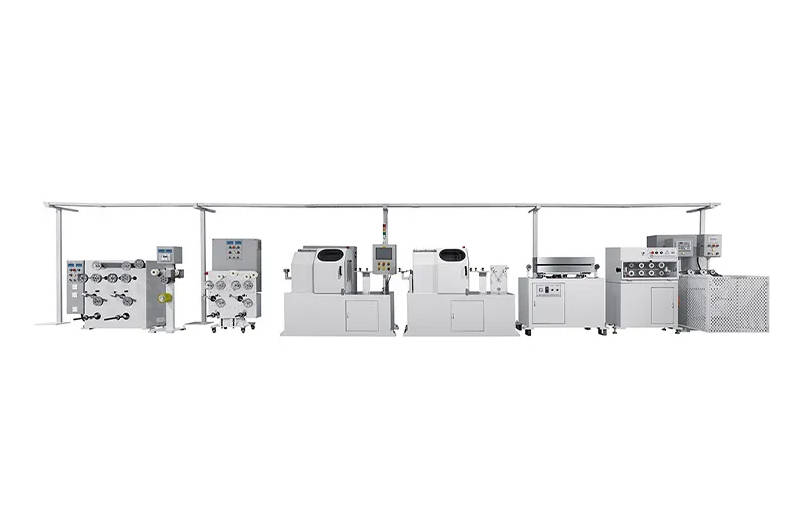

Frame-type stranding machine: Utilising a frame structure, the central shaft bears no load from the winding reel’s net weight. This design ensures high mechanical rigidity and hardness, delivering superior overall performance with a small turning radius and high processing speed.

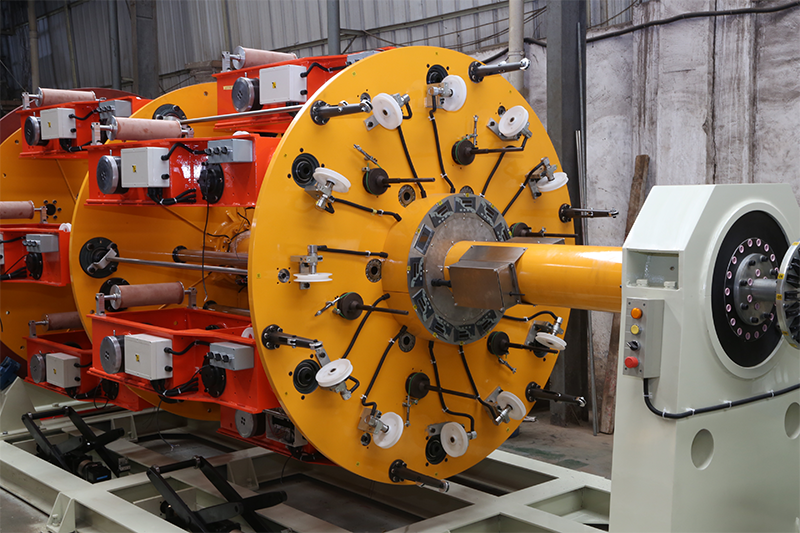

Cage-type stranding machine: The small turning radius necessitates a bulky untwisting device structure, which limits the processing speed of cage-type stranding machines.

2. Capability for Untwisting Stranding?

Frame Twister: Frame twisters cannot perform untwisting. During twisting, thermal stresses form in the single-wire tracks due to untwisting, causing high-strength hard-round transmission cables to twist loosely and become prone to strand separation. Therefore, some frame twisters incorporate pre-deformation equipment before the mixing cage to eliminate thermal stresses in the single-wire tracks.

Cage Stranders: Twist-relief stranding employs twist-relief rings, sprocket chains, and large planetary gears for twist relief. These mechanisms prevent single-wire tracks (e.g., optical fibre lines) from withstanding torque distances. High-tensile round wires (e.g., aluminium steel wires) and their twisted-pair cores must utilise cage stranders.

3. Insulated Cable Core Stranding

Frame-type stranding machine: As it cannot perform reverse stranding, it is only suitable for stranding small solid conductor ring-shaped insulated cable cores.

Cage-type stranding machine: Capable of both reverse and non-reverse stranding, it is suitable for all types of insulated cable cores.

4. Tension sensors

Frame stranding machine: Tension sensors are deployed using mechanical friction or pneumatic methods.