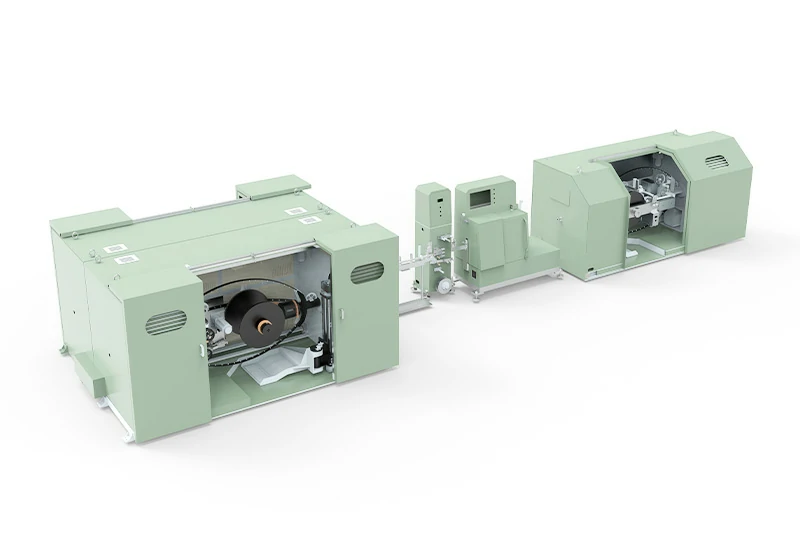

Bunching and Twisting Machine

Product Categories

Bunching and Twisting Machine

Product Positioning

Designed for precision bundling and stranding of electrical wires and cables, catering to applications ranging from low-voltage wiring to high-performance power cables. Engineered to enhance conductivity, mechanical strength, and flexibility, our machines are ideal for industries including power transmission, automotive, electronics, and renewable energy.

Functions & Value

- High-precision gear system ensures stranding pitch error ≤±0.5%.

- Automatic tension control adapts to copper, aluminum, and fiber materials.

- 7-inch touchscreen: Stores 100+ recipes, real-time parameter monitoring, and IoT remote diagnostics.

Company Advantages

- Established in 2000, serving 30+ global clients (TE, BELDEN , Amphenol).

- 25% R&D team with 16 patents (e.g.,uniform beam distribution, low-dose high-efficiency irradiation technology).

- CNC machining (±0.005mm precision) for durable components.

- Certifications: ISO 9001:2015, CE, UL/FDA compliant for export markets.

- Industry Kits: Pre-configured equipment for telecom (high-speed cable irradiation), automotive (harness cross-linking), and medical (sterilization).

- Fast Delivery: Standard models in 10 days, custom projects in 16 weeks (30% faster than industry average).

- Domestic: 4-hour remote response, 24-hour on-site service in major cities.

- International: 7×12-hour English support via local partners (Southeast Asia, Europe, N. America).

- Gold: 5-year extended warranty, annual precision calibration, and priority upgrade access.

- Platinum: Dedicated account manager, 24/7 remote monitoring, and free material testing.

- Free Training: Certified courses for operation, maintenance, and safety.

Why Choose Us?

Technology-Driven Performance

Metric | Our Equipment | Traditional Machines |

Max. Stranding Speed | 1,000 rpm (double twisting) | 500–600 rpm |

Pitch Uniformity | >99% | 95–97% |

Energy Consumption | 15–30 kW·h/shift | 40–60 kW·h/shift |

Unmatched After-Sales Commitment

- Free Process Simulation: Pre-purchase trial runs on customer-provided wire materials (copper, aluminum, or composite) to validate stranding pitch, tension control, and production efficiency. Our engineers will generate detailed reports on strand uniformity and recommend optimal machine configurations.

- Industry Partnerships: Collaborations with leading wire manufacturers (e.g., copper rod suppliers, insulation material vendors) to optimize stranding processes for specific applications (e.g., automotive harness durability, high-voltage cable conductivity).

- Technical Workshops: Free quarterly seminars on advanced stranding techniques, including case studies on reducing wire breakage rates and improving production line throughput.

Applications Across Industries

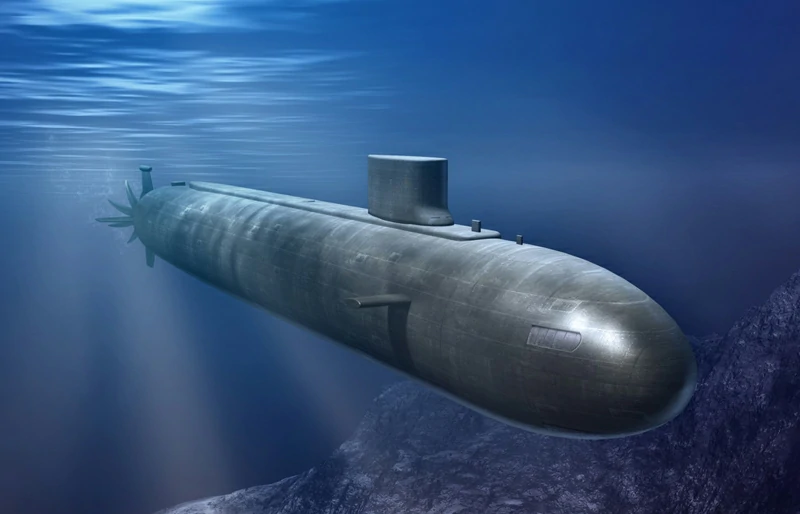

- High-voltage cable stranding for urban grids and subsea networks.

- ACSR cable bunching for overhead transmission lines.

- Twisting of high-voltage battery cables (800V+) for EVs.

- Stranding of ADAS sensor cables (LiDAR/RADAR) for signal stability.

- Ultra-fine bunching for USB-C, HDMI, and fiber optic cables.

- Twisted pair stranding for 5G base station wiring.

- Stranding of offshore wind farm cables (saltwater-resistant).

- Bundling of solar panel interconnection cables (UV-resistant).

Visual & Conversion Enhancements

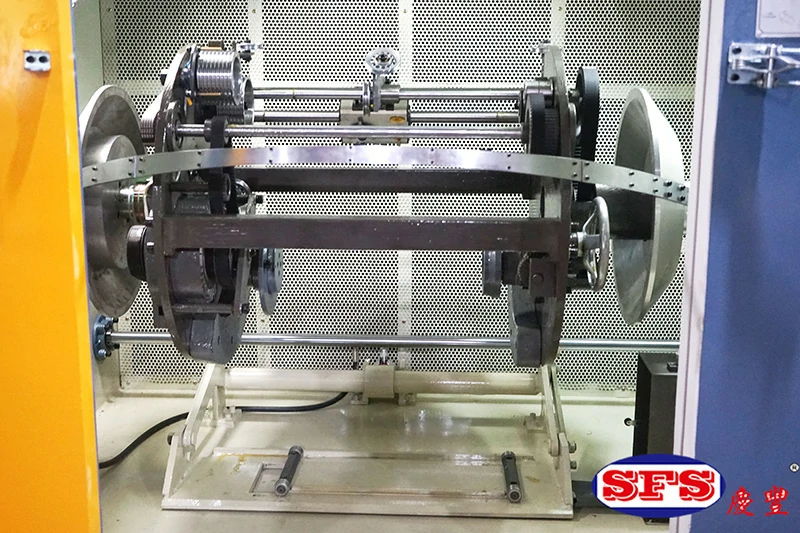

Showcase stranding mechanisms for different cable structures:

Thin-walled cables (e.g., automotive harnesses): 3D demo of high-speed cantilever twisting machines, highlighting real-time tension control and ultra-fine wire bunching processes (0.08–2.5 mm wire diameter).

Thick-insulation cables (e.g., 10kV power cables): Animated visualization of planetary cage twisting machines, demonstrating multi-layer stranding with precise pitch control (cable OD up to 120 mm) and armor wire integration. Comparative 3D models: Illustrate how double-twisting machines (e.g., 1250 New Bow Type) achieve 99% pitch uniformity vs. traditional single-twist equipment, with color-coded stress distribution maps for wire strands.

Virtual Machine Configuration Tool

Interactive interface allowing users to customize machine parameters (e.g., cage diameter, number of strands, rotation speed) and visualize real-time effects on cable structure (e.g., strand lay length, tensile strength simulation).

Frequently Asked Questions

Yes. We provide customized cabling and stranding solutions for armored cables, ribbon wires, high-frequency coaxial cables, and complex multi-core structures.

We also support full-line integration with extrusion and taping systems.

All machines are CE certified (EN 60204-1), equipped with emergency stop systems and overload protection.

Optional dust-proof or explosion-proof enclosures are available for harsh environments.

Standard warranty is 1 year, extendable to 5 years with our Premium Care Plan.

We maintain a 10-year inventory of critical components (motors, gears, bearings) and provide 48-hour fast dispatch service.

We offer a complete range of machines including:

• Planetary cage type twisting machines (Φ400–Φ1250) for heavy-duty core stranding

• Cantilever single and double twisting machines for LAN, data, and communication cables

• Bobbin-rotation type drum twisters for power cables and large-section conductors

• Non-backtwist cage-type machines for high-frequency and coaxial cables

• Vertical twisting machines for space-saving layout and vertical spooling

Looking For Wire and Cable Machine Manufacturer ?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.