Extrusion Line

Product Categories

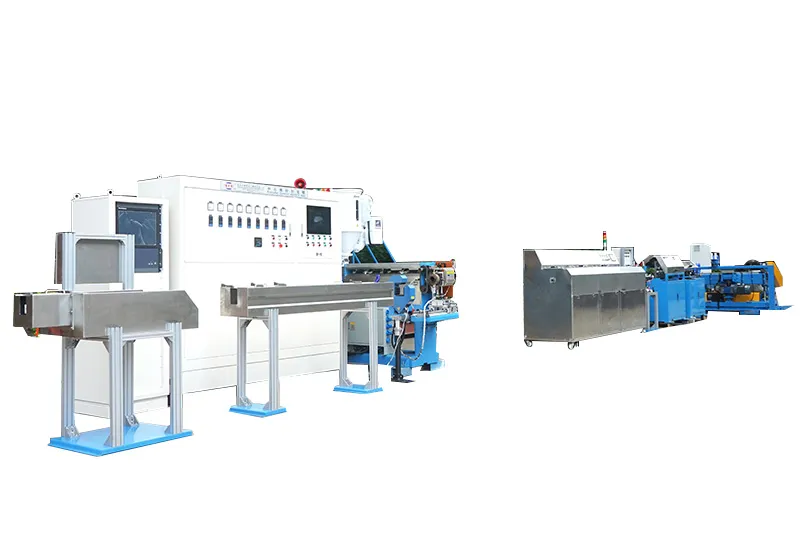

Cable Extrusion Line: Excellence in Manufacturing Innovation

Qingfeng’s high-performance extruders specialize in cable insulation and jacketing, provide precise solutions for various materials, meet diverse industrial needs, and deliver high-precision results as per specifications.

Major Features of Qingfeng Cable Extrusion Line

- Integrated energy recovery cuts power use, using less energy than conventional models.

- Low - noise designs enable quieter production.

- Advanced control for real - time accuracy.

- Advanced design and materials cut costs, reduce downtime.

- Compact layouts cut floor space by 30 - 40%, suiting factories with limited space.

- Modular design allows smooth integration.

- Supports 1 - 3 - layer extrusion for complex cables.

- Processes various materials, including Teflon, Nylon, PVC, etc., and polymers for extreme environments.

- Reaches up to 1200 meters per minute for high - throughput.

- Fully customizable parts meet unique product specs.

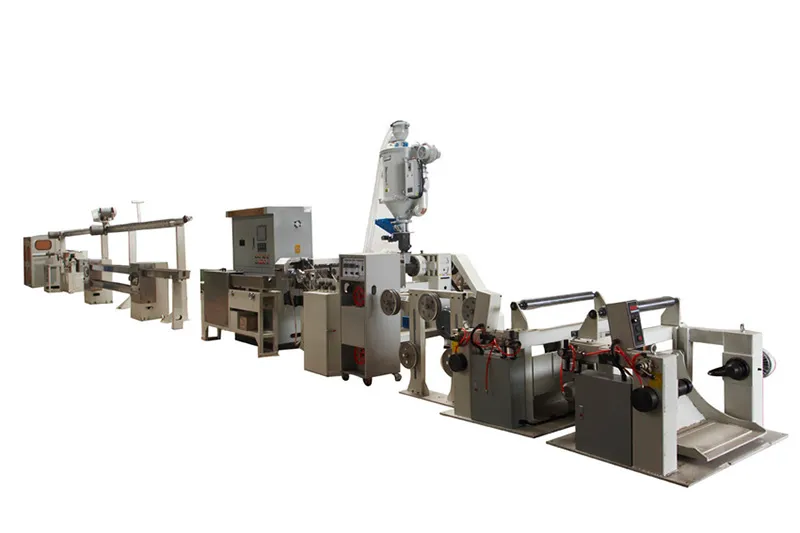

Optional Features of Extrusion Line

Qingfeng’s cable extrusion lines are flexible, with optional features to enhance performance and meet production needs, optimizing processes.

- Smart control systems use PLC + HMI touch interfaces for real - time monitoring and intuitive process adjustments.

- Automatic Online Inspection: Advanced detection ensures over 97% concentricity and defect - free output.

- Energy - Saving Extruders: Low - power models for eco - friendly manufacturers.

- High - Speed Modules: Retrofit kits boost production rates without quality loss.

Optional functions let manufacturers customize extrusion lines for diverse cable production needs.

Custom Cable Extrusion Line Solutions

- Factory Layouts: Modular setups optimize workflow for all factory sizes.

- Specialized Materials: Custom parts for micro - extrusion, foaming, and high - conductivity uses.

- Legacy Systems: Integrate smoothly with old equipment to boost productivity.

Applications of Cable Extrusion Line

Manufactures cables and wires for electric and traditional vehicles.

Produces wires and cables for reliable connectivity.

Makes flexible and reliable medical treatment cables.

Provides extrusion lines for renewable energy – related cables.

Wires for electronic devices like USB and LAN cables.

Cables for intelligent machines and robots.

Applications of Cable Extrusion Line

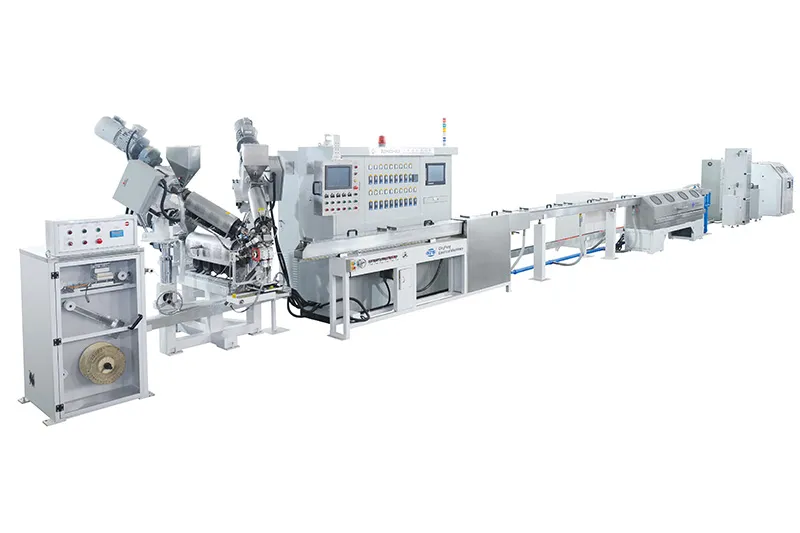

Key Advantages Over Conventional Technologies

- Lower Noise Emission: Quiet operation (<75 dB), meets industrial safety standards.

- Lower Space Requirement: Compact, up to 40% smaller than traditional extruders.

- Lower Energy Consumption: Energy - efficient, reduces power use by 25 - 30%.

- Longer Machine Lifetime:Heavy - duty parts and anti - wear coatings enable 8 - 10 years of reliable use.

- Stable Process Control: Advanced temperature control and real - time pressure monitoring ensure consistent extrusion quality.

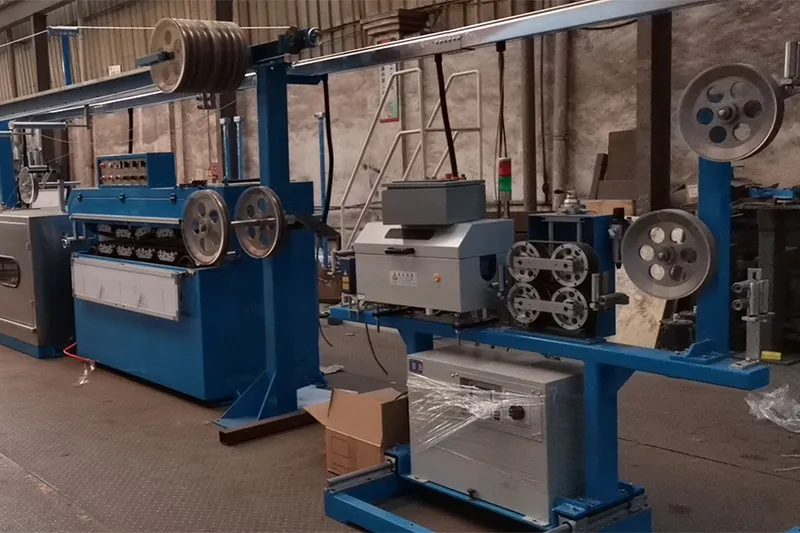

Quality Control in Qingfeng Extrusion Lines

Quality is at the core of Qingfeng; Rigorous quality control ensures the performance and reliability of the extrusion production line:

- Tight tolerances on diameter and temperature ensure quality.

- Advanced Online Detection: Automated systems monitor and adjust production in real - time.

- Comprehensive Monitoring: Multi - point monitoring ensures cables meet standards.

- Specialized Testing Equipment: Enables high concentricity and accurate wall thickness.

- Certifications and Standards: Meets international quality standards.

Ensures cables meet top industry standards.

Why 600+ Clients Choose Qingfeng Cable Extrusion Line

Frequently Asked Questions

Qingfeng provides a diverse range, including Teflon (High-Frequency Wire), Teflon Physical Foaming, Chemical Foaming, Nylon (Flat Copper Strip), Photovoltaic and Wind Energy, Insulating Core Wire, Sheathing and Power Cable, Intelligent Machine and Medical Treatment, and Double Wire Extrusion Lines.

Our lines process materials like Teflon (FEP, PFA, ETFE), Nylon, PVC, PE, TPU, LSZH, XLPE, TPV, Foam-PE, HDPE, PU, PP, and more.

Depending on the model and application, speeds range from 10 m/min to 600 m/min.

Through precision engineering, advanced online detection, comprehensive monitoring, specialized testing, and ISO9001 certification.

Features include advanced control systems, automatic detection, energy-efficient designs, custom screw designs, and high-speed production capabilities.

Lead times vary based on customization,contact us for specific timelines.

Looking For Wire and Cable Machine Manufacturer ?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.