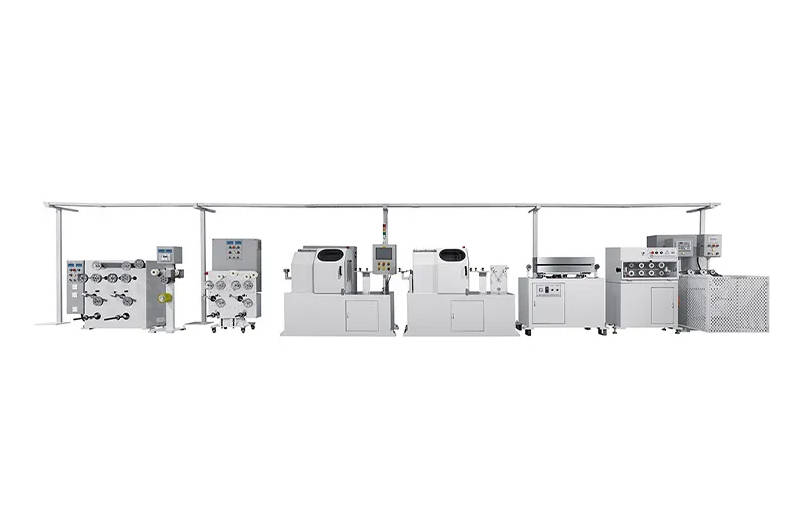

In the high-precision world of cable manufacturing, the integrity of the final product depends heavily on how individual wires or fibers are laid together. For specialized cables such as Optical Ground Wire (OPGW), submarine power cables, and extra-high-voltage conductors, the industry standard is the Planetary Stranding Machine.

The defining feature of this equipment is the back-twist mechanism. Understanding how this mechanism works—and why it is superior to rigid stranding for specific applications—is critical for factory owners and engineers aiming to minimize material fatigue and maximize cable longevity.

1. Introduction: The Necessity of Stress-Free Stranding

In conventional “rigid” stranding, the bobbins are fixed within a rotating cage. As the cage spins, the wire is pulled off and twisted 360 degrees for every single revolution of the machine. This introduces significant torsional stress (internal twist) into the wire. For simple copper or steel ropes, this might be acceptable. However, for complex or sensitive materials, this internal stress leads to “bird-caging,” unraveling, or even micro-fractures in optical fibers.

The back-twist mechanism in a planetary stranding machine works by rotating the bobbin cradles in the opposite direction of the main cage’s rotation to cancel out the mechanical twist, ensuring that the wire remains in a neutral, stress-free state as it is laid into the cable.

By neutralizing this torsion, manufacturers can produce cables that are perfectly balanced, do not twist when cut, and maintain their structural integrity over decades of service in harsh environments.

2. What is “Back-twist” in Cable Stranding?

To visualize back-twist, imagine holding a bobbin in your hand. If you walk in a circle while keeping your body facing the center of that circle, you are effectively “rotating” the bobbin. This is what happens in a rigid strander.

In a Planetary Strander, as the main cage rotates 360 degrees clockwise, a mechanical linkage rotates the bobbin cradle 360 degrees counter-clockwise. Consequently, the bobbin always maintains its orientation relative to the ground (e.g., the top of the bobbin always points toward the ceiling).

Key Concepts:

- 100% Back-twist: The cradle rotates exactly one full turn backward for every turn of the cage. The wire experiences zero torsion.

- Variable Back-twist: Some advanced planetary machines allow for “partial” back-twist (e.g., 50% or 110%) to compensate for specific material elasticities or “over-lay” requirements.

- Neutral Axis: The goal of back-twist is to ensure the wire’s longitudinal axis remains straight, preventing the buildup of potential energy that causes “spring-back.”

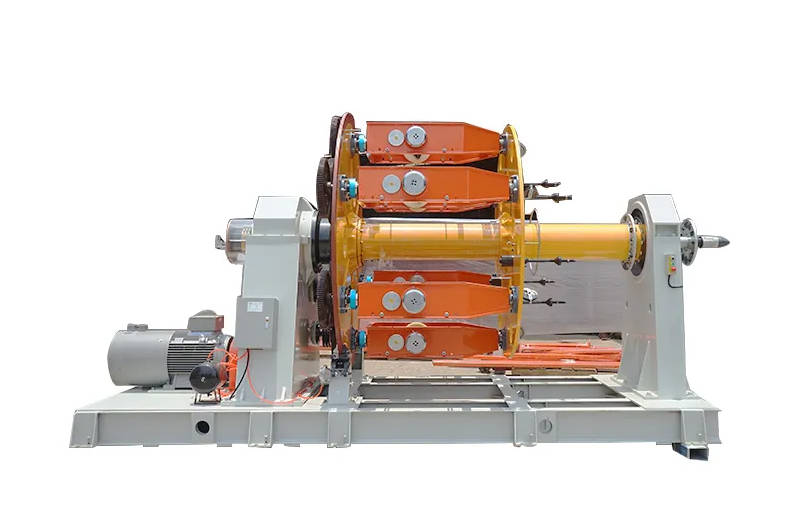

3. The Mechanical Logic: How the Mechanism Works

The “Planetary” name is derived from the Planetary Gear System used to drive the cradles. The engineering behind this is a marvel of synchronized motion.

The Sun and Planet Gear Arrangement

At the heart of the machine is a central “Sun” gear (which is often stationary or independently driven) and multiple “Planet” gears attached to the bobbin cradles.

- The Main Cage: Driven by a high-torque motor, it rotates the entire assembly.

- The Transmission Shaft/Chain: A secondary drive system connects the sun gear to the planet gears located at each bobbin station.

- Cradle Synchronization: As the cage turns, the planet gears “walk” around the sun gear. Because of the gear ratio, this motion forces the bobbin cradle to rotate backward at a precisely synchronized speed.

Structural Components

- The Cradles: These are the heavy-duty frames that hold the bobbins. They must be perfectly balanced to prevent vibration at high speeds.

- Support Bearings: High-precision bearings are used at both ends of the cradle to allow smooth back-rotation while under the centrifugal force of the rotating cage.

- Tension Control: Integrated into the cradle is a braking or motorized system to ensure the wire is released at a constant tension, regardless of the bobbin’s weight or the cage’s speed.

4. Key Benefits of Using the Back-twist Mechanism

Why should a manufacturer invest in a planetary machine when rigid stranders are often faster and cheaper? The answer lies in the quality of the lay.

Elimination of Residual Torsion

The primary benefit of a planetary stranding machine is the total elimination of residual torsion, which prevents the finished cable from kinking, looping, or deforming when it is unspooled or cut during installation. This is a non-negotiable requirement for submarine cables that must lie flat on the seabed.

Handling Sensitive Materials

Materials like Aluminum Clad Steel (ACS) or delicate optical fiber tubes are highly sensitive to twisting. Back-twist ensures that these materials are only bent (to form the helix) but never twisted (around their own axis). This prevents the “bird-cage” effect, where individual wires pop out of the stranded structure.

Superior Flex Life

Cables produced with 100% back-twist have a significantly longer flex life. Because the wires are not under internal stress, they can withstand more bending cycles in dynamic applications, such as wind turbine cables or robotic umbilical lines.

5. Comparing Planetary vs. Rigid vs. Tubular Stranders

When choosing a machine, it is vital to understand where the Planetary Strander fits in the production hierarchy.

| Feature | Planetary Strander | Rigid Strander | Tubular Strander |

| Back-twist Capability | 100% (or Adjustable) | None (0%) | None (0%) |

| Production Speed | Low to Medium | High | Very High |

| Torsional Stress | Zero / Neutral | High | High |

| Ideal Materials | OPGW, Submarine, ACS, Fiber | Copper/Aluminum Conductor | Small Steel Ropes/Wire |

| Internal Tension | Extremely Low | Moderate | Moderate |

| Footprint | Large | Medium to Large | Small/Compact |

The Decision Matrix: If your priority is output volume for standard electrical house wiring, a Rigid or Tubular strander is best. If your priority is precision and structural stability for high-value specialty cables, the Planetary Strander is the only viable option.

6. Common Technical Questions from Users

Q1: Does the back-twist mechanism limit the production speed?

Yes. Because the bobbin cradles are rotating and have significant mass, centrifugal forces become a limiting factor. Planetary machines typically operate at lower RPMs (e.g., 50–150 RPM) compared to rigid stranders (which can exceed 300+ RPM). However, the value of the resulting cable is significantly higher.

Q2: Is the back-twist mechanism difficult to maintain?

The planetary gear system and the cradle bearings require regular lubrication and inspection. Modern machines utilize automatic oiling systems and vibration sensors to detect bearing wear before it leads to a breakdown. Compared to rigid machines, the maintenance load is slightly higher due to the increased number of moving parts.

Q3: Can I turn the back-twist off?

Most high-end planetary machines allow for the locking of the cradles, effectively turning the machine into a rigid strander. This provides manufacturers with the flexibility to produce both high-precision cables and standard conductors on a single machine.

7. Applications: Where Planetary Stranding is Non-Negotiable

OPGW (Optical Ground Wire)

OPGW consists of a central tube containing optical fibers, surrounded by layers of aluminum-clad steel or aluminum alloy wires. The use of back-twist in OPGW production is mandatory because any torsion applied to the steel wires would put immense pressure on the central optical tube, potentially crushing the fibers or causing signal attenuation.

Submarine and Umbilical Cables

These cables can be hundreds of kilometers long. If even a small amount of torsion is built up over that length, the cable will become unmanageable during deployment. Planetary stranding ensures the cable remains “dead”—meaning it has no tendency to twist on the ocean floor.

Large Cross-Section Sector Conductors

When stranding large, shaped (sector) conductors, the orientation of each segment is critical. The back-twist mechanism allows for the precise positioning of each sector so they fit together like a perfect puzzle, minimizing the overall diameter of the cable.

8. Conclusion: Choosing the Right Planetary Machine

Investing in a Planetary Cable Machine is a strategic move for manufacturers targeting high-margin, high-specification contracts. When evaluating a machine, do not just look at the price; look at the precision of the back-twist synchronization.

The quality of a planetary stranding machine is determined by the robustness of its cradle support system and the precision of its gear transmission, as even a 1% error in back-twist can lead to significant residual stress in long-distance cables.

What to look for in a manufacturer:

- Gear Precision: Heat-treated, ground gears for silent and smooth synchronization.

- Tension Control: Electronic hysteresis brakes or AC servo-driven active payoff for consistent wire tension.

- Automation: PLC-controlled pitch and back-twist adjustment.

If your facility is moving into the production of renewable energy cables or telecommunications infrastructure, mastering the back-twist mechanism is your first step toward market leadership.