The global demand for electricity is undergoing a transformation. From the rapid urbanization requiring massive amounts of low-voltage building wires to the modernization of national grids demanding ultra-reliable high-voltage transmission lines, the pressure on cable manufacturers is immense. At the heart of this supply chain sits a critical piece of machinery: the Wire Extrusion Line.

For manufacturers, investing in an extrusion line is a significant capital expenditure. However, the term “Wire Extrusion Line” is a broad umbrella. The technology required to produce a standard 2.5mm² PVC housing wire is vastly different from the engineering marvels needed to produce a 132kV XLPE underground cable.

This comprehensive guide explores the technical distinctions, operational challenges, and strategic solutions provided by modern extrusion lines for both Low-Voltage (LV) and High-Voltage (HV) applications. Whether you are aiming for high-speed mass production or precision engineering for critical infrastructure, understanding these differences is key to optimizing your factory’s ROI.

I. Introduction: The Two Worlds of Cable Manufacturing

While the fundamental principle of extrusion—melting plastic pellets and applying them over a metal conductor—remains constant, the execution varies dramatically based on voltage class.

- Low-Voltage (LV) Manufacturing is a game of speed and efficiency. Margins are tight, and volume is king. The machinery must be robust, capable of running at breakneck speeds, and adaptable to frequent color changes.

- High-Voltage (HV) Manufacturing is a game of purity and precision. A microscopic void or a speck of dust in the insulation of a high-voltage cable can lead to catastrophic electrical breakdown years after installation. Here, the machinery prioritizes material stability and the complex chemistry of cross-linking.

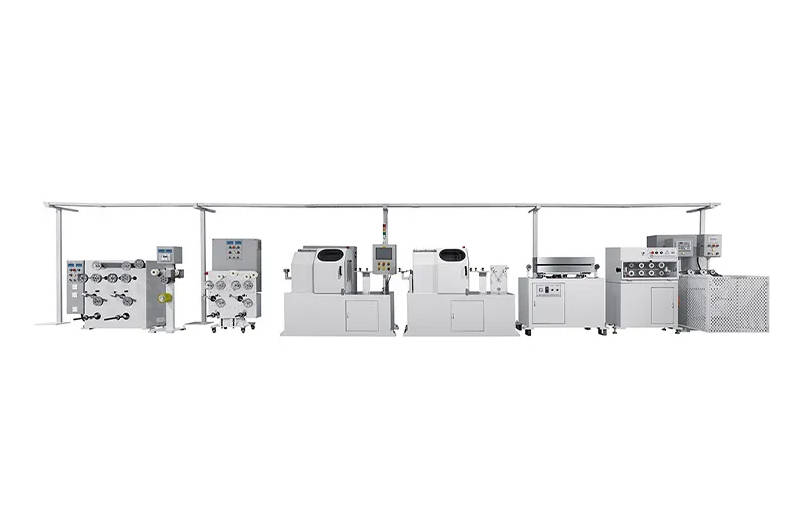

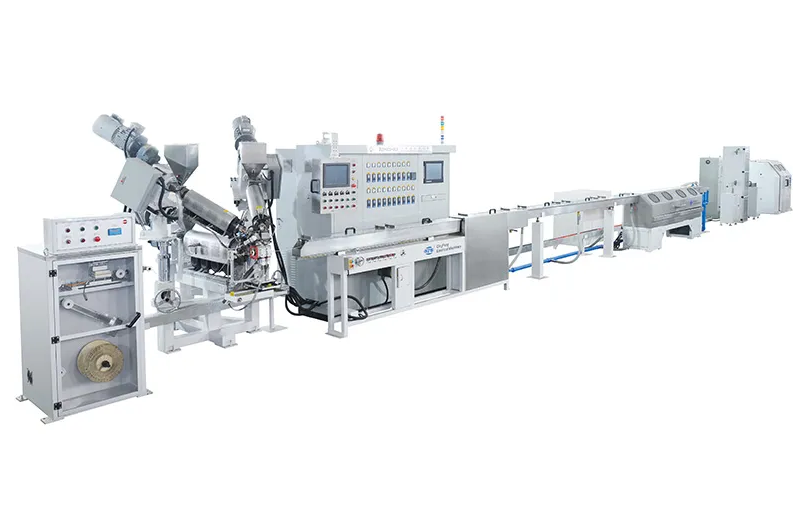

A Wire Extrusion Line is an integrated system comprising a payoff, pre-heater, extruder (screw and barrel), crosshead, cooling trough, capstan, and take-up. Its primary function is to apply a uniform insulation layer over a copper or aluminum conductor.

In the sections below, we will dissect how these lines are specialized for their specific tasks.

II. Low-Voltage (LV) Solutions: Maximizing Speed and Output

Low-voltage cables (typically rated up to 1kV) include building wires, automotive cables, and control cables. The primary insulation materials are PVC (Polyvinyl Chloride), PE (Polyethylene), and increasingly, LSZH (Low Smoke Zero Halogen).

For manufacturers in this sector, the primary challenge is achieving the highest possible Line Speed (m/min) without sacrificing surface quality or concentricity.

1. High-Speed Tandem Extrusion

Modern LV extrusion lines are designed for speed. For small cross-section wires (e.g., 0.5mm² – 2.5mm²), top-tier machines can achieve production speeds exceeding 1000 to 1200 meters per minute.

To maintain this output, manufacturers often utilize Tandem Extrusion. This setup involves two extruders arranged in series:

- The first extruder applies the main insulation layer.

- The second extruder applies a thin “skin” layer or color stripes.

2. The “Skin/Stripe” Technology: Cutting Costs

One of the most effective ways to solve the user pain point of “downtime due to color changes” is through Co-Extrusion technology.

In the past, to change a wire color from Red to Blue, the operator had to stop the line, purge the main extruder, clean the screw, and restart—a process wasting hours and kilograms of material.

Modern LV Wire Extrusion Lines utilize a “Skin” method where the main extruder runs a neutral (natural) color material 100% of the time. A smaller, auxiliary co-extruder injects a thin layer of colored masterbatch on the surface (the skin).

This technology offers two massive benefits:

- Instant Color Change: You only need to purge the small auxiliary extruder, which takes minutes rather than hours.

- Material Cost Savings: Colored masterbatch is expensive. By restricting the color to the outer 10% of the insulation thickness, manufacturers significantly reduce their raw material costs.

3. Automatic Dual-Flyer Take-Up

Speed at the extruder is useless if you cannot coil the wire fast enough. For LV lines, Dual-Flyer Automatic Take-ups are essential. These machines automatically cut the wire and switch to a fresh empty reel at full line speed, ensuring 24/7 continuous operation.

III. High-Voltage (HV) Solutions: The Triple-Layer (CCV) Technology

Moving to High-Voltage (HV) and Extra-High-Voltage (EHV) cables (ranging from 10kV to 500kV), the manufacturing process changes from a physical one (melting) to a chemical one (cross-linking).

The standard insulation material here is XLPE (Cross-Linked Polyethylene) or EPR (Ethylene Propylene Rubber). These materials must be chemically cured to withstand high temperatures and electrical stress.

1. The CCV Line (Catenary Continuous Vulcanization)

High-voltage cables are heavy. If you try to cure a thick, hot XLPE cable in a straight horizontal line, gravity will pull the insulation down, causing it to become pear-shaped (eccentric).

To produce High-Voltage cables, manufacturers use a CCV Line (Catenary Continuous Vulcanization). In this system, the extruded cable is suspended in a catenary curve (a controlled sag) inside a long, heated curing tube. By calculating the precise tension and curve, gravity is counteracted, ensuring the insulation remains perfectly round.

2. Triple-Layer Extrusion (One Head, Three Layers)

Unlike LV wires which usually have a single layer, HV cables require a complex “sandwich” structure to control the electric field. This is achieved via a Triple-Layer Crosshead.

The Triple-Layer Extrusion process simultaneously applies three distinct layers in a single pass: the inner semi-conductive screen (to smooth the conductor), the XLPE insulation (the main dielectric), and the outer semi-conductive screen (to contain the electric field).

This “Wet-on-Wet” application is crucial. If these layers were applied separately, air or dust could get trapped between them, creating localized areas of high electrical stress (partial discharge) that would eventually cause the cable to explode.

3. Dry Curing: Why Nitrogen?

A critical question from new HV manufacturers is: “Why do we need Nitrogen gas?”

In the past, steam was used to cure XLPE (Steam Curing). However, steam introduces moisture into the insulation. Under high voltage, this moisture forms microscopic channels known as “Water Trees,” which slowly degrade the insulation strength.

Modern HV Extrusion Lines employ “Dry Curing” using pressurized Nitrogen gas. Nitrogen provides the necessary pressure to prevent voids from forming during the chemical cross-linking process but, unlike steam, it is inert and dry. This eliminates the risk of water trees and significantly extends the service life of the cable.

IV. Critical Component Comparison: LV vs. HV Lines

To help you understand the engineering differences, we have compiled a comparison of the critical components found in these two types of extrusion lines.

| Component | Low-Voltage (LV) Line | High-Voltage (HV / CCV) Line |

| Primary Material | PVC, PE, Nylon, LSZH. | XLPE, EPR (Cross-linkable). |

| Screw Design | Barrier Screw: Designed for high shear and mixing to melt PVC quickly. L/D Ratio usually 24:1 or 26:1. | Low-Shear Screw: Designed to melt XLPE gently to prevent “scorching” (premature curing) in the barrel. L/D Ratio often 30:1. |

| Crosshead Type | Single or Dual Layer: Self-centering, fixed-center, or manual adjustment. Focus on easy flow. | Triple Layer Head: Extremely complex flow channels to balance three viscosities. Must include precise oil temperature control. |

| Cooling/Curing | Water Trough: Simple multi-pass cooling troughs using ambient or chilled water. | Vulcanization Tube: A 100m+ long sealed tube filled with pressurized Nitrogen (10-12 bar) and heated to 300°C+. |

| Material Handling | Standard vacuum loaders and dryers. | Clean Room Class 1000: Material is handled in a sealed, dust-free environment. Use of gravitational feeding to avoid friction dust. |

| Quality Control | Spark Tester, Laser Diameter Gauge. | X-Ray Concentricity Gauge: Measures wall thickness and concentricity of all 3 layers blindly inside the tube. |

V. Solving Common User Pain Points

When we speak to factory managers, their concerns rarely revolve around the “features” of the machine, but rather the “problems” they face daily. Here is how advanced Wire Extrusion Lines address these common issues.

Pain Point 1: “We waste too much material during startup.”

Every time an extrusion line starts, there is a ramp-up period where the cable produced is scrap because the outer diameter (OD) hasn’t stabilized. For large HV cables, this scrap can cost thousands of dollars per startup.

- The Solution: Synchronized Start-up Control.

High-end lines use sophisticated PLC algorithms (Siemens or Rockwell) that link the extruder RPM, capstan line speed, and crosshead temperature into a single “Recipe.” When the operator hits “Start,” the machine ramps up all parameters in perfect synchronization. This reduces the “start-up scrap length” from hundreds of meters to just a few meters.

Pain Point 2: “Our cables fail the concentricity test, wasting expensive copper.”

If the insulation is not perfectly centered, you must add more plastic insulation to ensure the thinnest point meets the minimum standard (IEC or UL). This means you are essentially giving away free plastic, or worse, your conductor is off-center.

- The Solution: X-Ray Eccentricity Management.

By integrating an online X-ray measurement system (like Sikora or Zumbach) directly with the extrusion crosshead, the line can perform Automatic Centering. The system detects a deviation of even 0.01mm and automatically adjusts the centering bolts (motorized crosshead) to bring the conductor back to the geometric center. This can save manufacturers 2-5% on total material costs annually.

Pain Point 3: “The XLPE material scorches (burns) in the extruder.”

XLPE is heat-sensitive. If it stays in the barrel too long or gets too hot, it cures inside the machine (“Scorching”), creating lumps on the wire surface.

- The Solution: Optimized Screw Geometry & Temperature Control.

HV Extrusion lines utilize “Super-Cooling” blowers and screws with specialized mixing sections that generate minimal friction heat. Furthermore, the barrel lining is often made of Bimetallic alloys that are ultra-smooth to prevent material stagnation.

VI. Buying Guide: Choosing the Right Line for Your Factory

If you are in the market for a new Wire Extrusion Line, do not simply buy “off the shelf.” The configuration must match your specific product mix.

1. Determining the Screw Size

The size of the extruder (Screw Diameter) determines your output capacity.

- 45mm – 60mm: Ideal for small hook-up wires, automotive wires, and striping.

- 70mm – 90mm: The workhorse for building wires (1.5mm² to 16mm²).

- 120mm – 150mm: Required for heavy power cables and sheathing (Jacketing) lines.

2. Versatility vs. Specialization

A common mistake is trying to buy one line to “do it all.”

- Can you run PVC on an XLPE line? Technically, yes.

- Should you? No. The screw designs are different. Running PVC on a specialized XLPE screw will result in poor mixing and low output. Running XLPE on a PVC screw will cause scorching.

- Recommendation: Dedicate specific lines to specific material groups (Halogen-free lines, PVC lines, and XLPE lines) to maximize efficiency and reduce cleaning downtime.

3. Component Brands Matter

An extrusion line is a chain; it is only as strong as its weakest link. Ensure your supplier uses:

- Motors: Siemens or ABB (for energy efficiency).

- Drives: Danfoss or Yaskawa (for precise speed control).

- Gearbox: Hardened face gearboxes (like Zambello) to withstand the high back-pressure.

VII. Conclusion

The manufacturing of electrical cables is the foundation of modern infrastructure, and the Wire Extrusion Line is the engine that drives it. Whether you are producing Low-Voltage building wires where speed and automation determine your profit margin, or High-Voltage transmission cables where material purity and triple-layer precision determine the safety of the grid, the technology you choose matters.

Successful cable manufacturers understand that an extrusion line is not just a plastic melter—it is a sophisticated system of thermal, mechanical, and electrical control. By leveraging technologies like Skin/Stripe Co-extrusion, CCV Nitrogen Curing, and X-Ray Centricity Control, you can transform your production from a simple manufacturing process into a competitive advantage.

Ready to Configure Your Production Line?

Choosing the right Wire Extrusion Line requires a deep analysis of your cable specifications, voltage ratings, and material types. Don’t leave your production quality to chance. Contact industry experts to discuss a tailored solution that balances high-speed output with zero-defect reliability.