I. Introduction: The 224G Paradigm Shift

The global appetite for data is insatiable. As we transition from 400G and 800G towards 1.6T networking architectures, the physical layer is under unprecedented pressure. At the heart of this evolution is the 224G per lane (PAM4) standard, which represents the current frontier for Direct Attach Cables (DACs). While fiber optics are essential for long-haul transmission, high-speed copper DACs remain the most cost-effective, energy-efficient solution for short-reach intra-rack connections in AI-driven data centers.

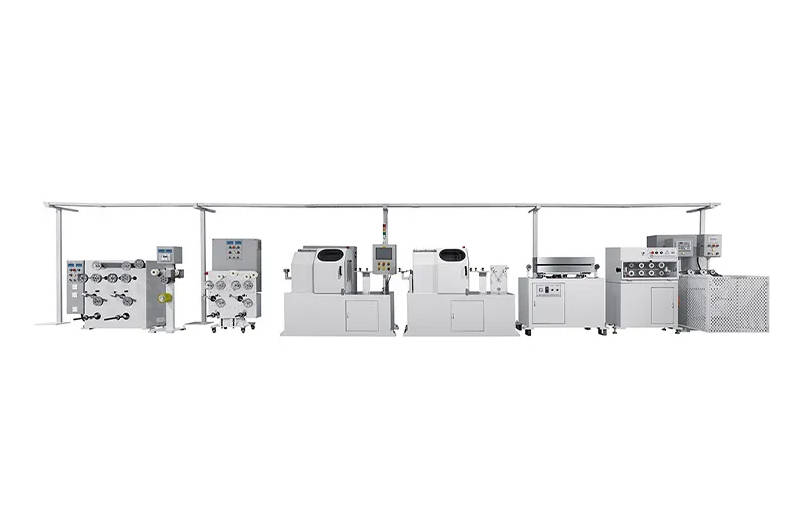

However, moving from 112G to 224G is not merely a linear upgrade; it is a fundamental shift in physics. At these frequencies, the copper wire behaves more like a waveguide, and even the smallest physical imperfection becomes a catastrophic signal integrity (SI) failure. A high-speed taping machine for 224G DACs must achieve micron-level precision to ensure that the shielding and insulation layers are applied with absolute uniformity, as any mechanical deviation directly manifests as electromagnetic interference.

For cable manufacturers, the challenge is clear: traditional taping equipment designed for lower speeds can no longer meet the stringent “Zero-Error” tolerance required for 224G interconnects. This article explores how precision alignment in advanced taping machinery is the decisive factor in overcoming crosstalk and securing a competitive edge in the next-generation networking market.

II. Understanding the Relationship Between Taping and Crosstalk

Defining Crosstalk at High Frequencies

In the context of 224G DACs, crosstalk is the unwanted transfer of signals between communication channels. At 112GHz Nyquist frequency, the electromagnetic fields extend further from the conductor. We categorize these into:

- Near-End Crosstalk (NEXT): Interference occurring at the transmitter end.

- Far-End Crosstalk (FEXT): Interference measured at the receiver end.

The Impedance Factor

The Characteristic Impedance ($Z_0$) of a Twinax cable is determined by the ratio of the conductor diameter to the distance between the conductors and the shielding. In 224G manufacturing, a taping machine that provides inconsistent tension or uneven tape overlap creates “impedance bumps.” These bumps cause signal reflections (Return Loss) and increase the total crosstalk budget of the system.

Differential Pair Symmetry and Skew

A Twinax cable relies on two parallel conductors. For the signal to remain “clean,” these two wires must be identical in every physical aspect. If the taping machine applies more pressure or a different overlap pitch to one wire than the other, it introduces Intra-pair Skew. At 224G, a skew of just a few picoseconds can cause the differential signal to collapse, leading to unrecoverable bit errors.

III. Critical Challenges in 224G Cable Manufacturing

Manufacturing 224G DACs involves handling materials that are increasingly delicate. The pursuit of lower signal loss has led to the use of thinner foils and more fragile dielectrics.

1. Material Sensitivity

Most 224G cables utilize Al-Mylar (Aluminum-Polymer) for shielding and PTFE (Polytetrafluoroethylene) or PFA for insulation. These materials have a high “stretch factor.” If a taping machine applies too much tension, the tape thins out, changing its dielectric properties. If it applies too little, “air pockets” form between the layers, causing unpredictable impedance spikes.

2. The Overlap Dilemma

The overlap of the shielding tape (typically 25% to 50%) must be constant. At 224G, a variance in tape overlap exceeding ±0.05mm can lead to a failure in the Integrated Crosstalk Noise (ICN) test. Maintaining this level of precision while the machine is running at high speeds (RPM) is the primary engineering hurdle for manufacturers.

3. High-Speed Stability

Throughput is essential for ROI. However, as the rotation speed of the taping head increases, centrifugal forces can cause the tape path to vibrate. Any micro-oscillation in the taping head results in a “periodic defect” in the cable, which creates a resonance peak at specific frequencies—effectively acting as a filter that kills the signal.

IV. Solving Common User Pain Points: The Precision Alignment Solution

When users search for a High-speed Taping Machine, they aren’t just looking for a motor that spins; they are looking for a solution to their “yield rate” problems. Here is how modern precision alignment addresses those concerns.

Active Tension Control Systems

Traditional machines use mechanical friction brakes to control tape tension. These are reactive and inconsistent. The highest-performing taping machines for 224G DACs utilize active servo-driven tensioners. These systems use ultra-sensitive load cells to measure tension in real-time, adjusting the torque of the tape spool thousands of times per second to maintain a constant force.

Laser-Guided Centering and Vision Systems

Human error in machine setup is a major cause of scrap. Modern machines integrate laser displacement sensors that monitor the position of the conductor as it enters the taping head. If the wire deviates by even 10 microns from the center of the taping axis, the machine’s vision system automatically compensates the alignment guides to prevent asymmetrical wrapping.

Synchronized Pitch Precision

The “Pitch” (the distance between each wrap of the tape) must be perfectly correlated with the linear speed of the wire. This requires a sophisticated “Electronic Line Shaft” (ELS) where the taping head and the caterpillar (pulling unit) are locked in a digital master-slave relationship via PLC.

| Feature | Legacy Taping Machine | 224G Precision Taping Machine | Impact on Signal Integrity |

| Tension Control | Manual/Friction Brake | Active Servo-Loop | Reduces dielectric thinning/air gaps |

| Pitch Tolerance | ±0.2 mm | ±0.02 mm | Minimizes periodic resonance |

| Max RPM | 1500 – 2000 | 3000 – 5000 | Increases ROI without losing SI |

| Alignment | Mechanical Fixed Guides | Laser-Guided Active Alignment | Ensures perfectly symmetrical Twinax |

| Data Tracking | None | Real-time SI-Parameter Logging | Guaranteed traceability for clients |

V. Essential Features of a High-Speed Taping Machine for 224G

If you are in the market for a new production line, these are the non-negotiable specifications for 224G capability:

1. Vibration Damping Architecture

The machine frame should be constructed from high-mass, vibration-absorbing materials (such as specialized cast iron or mineral casting). Vibration damping is critical because mechanical micro-vibrations at the taping head translate into “jitter” in the electromagnetic shield, which directly increases the FEXT (Far-End Crosstalk) of the finished DAC.

2. Multi-Layer Co-Axial Taping

To reduce the number of times the cable is handled (which can cause physical damage), look for machines that can apply multiple layers—such as the silver-plated copper wire, the Al-Mylar shield, and the outer jacket tape—in a single pass. This ensures that the alignment between layers remains “locked” throughout the process.

3. Integrated Spark Testing and Diameter Control

A high-speed taping machine should include an inline laser micrometer to monitor the outer diameter (OD) and a high-frequency spark tester to detect insulation defects immediately. This allows for real-time rejection of non-compliant segments before they reach the spooling stage.

VI. Operational Best Practices for Manufacturers

Even the best High-speed Taping Machine requires a controlled environment to produce 224G-grade cables.

- Environmental Control: The room temperature must be maintained within ±2°C. Thermal expansion of the machine components or the copper conductor can shift the alignment enough to fail 224G specs. Humidity control is equally important to prevent static build-up on the Mylar tape.

- Calibration Protocols: Manufacturers should perform a “Golden Cable” calibration weekly. This involves running a test length and measuring it on a Vector Network Analyzer (VNA) to ensure the machine’s physical output matches the required electrical performance.

- Tooling Selection: Use ceramic-coated guides or polished tungsten carbide rollers. Any scratch on the tape or the conductor during the taping process will create a point of signal leakage.

VII. Future-Proofing: Beyond 224G

The industry is already looking toward 448G. While this may seem far off, the machines being purchased today will likely be expected to handle the transition. Investing in a taping machine with an open-architecture PLC and modular taping heads is essential for future-proofing. As frequencies increase, the ability to upgrade to even higher-precision tensioners or AI-driven defect detection will be the difference between a relevant factory and an obsolete one.

Artificial Intelligence (AI) is beginning to play a role in “Predictive Alignment.” By analyzing the data from thousands of kilometers of cable, these machines can predict when a tape spool is likely to wobble or when a bearing is starting to wear out, allowing for maintenance before the cable quality drops.

VIII. Conclusion: Precision as a Competitive Advantage

In the world of 224G DACs, there is no “good enough.” The electrical performance of the cable is a direct reflection of the mechanical precision of the taping process. By utilizing high-speed taping machines equipped with active tension control, laser alignment, and vibration-damped frames, manufacturers can drastically reduce crosstalk and return loss, ensuring their products meet the rigorous standards of the world’s leading data centers.

When you choose a taping solution, you are not just buying a piece of hardware; you are buying the ability to guarantee signal integrity at the edge of physical limits. Precision alignment is no longer an optional feature—it is the core requirement for the 224G era.