Polyethylene (PE) is arguably the most versatile polymer in the wire and cable industry. Its applications range from the rugged, weather-resistant outer jacketing of high-voltage underground cables to the delicate, microscopic insulation of high-frequency LAN cables (Cat 6/7) and 5G coaxial lines.

However, for factory managers and process engineers, PE presents a unique set of manufacturing challenges. Unlike PVC, which is relatively forgiving, Polyethylene is a crystalline polymer. It shrinks significantly upon cooling, requires precise temperature management to prevent “melt fracture,” and necessitates advanced screw designs to ensure homogeneity.

This comprehensive guide breaks down the engineering behind PE Wire Extrusion Lines. We will explore how machinery configurations differ between simple Low-Voltage sheathing and advanced High-Speed physical foaming, helping you select the right equipment for your production goals.

I. Introduction: The Versatility and Challenge of Polyethylene

Why is PE so popular? In the world of signal transmission, “Dielectric Constant” ($D_k$) is king. The lower the $D_k$, the faster the signal travels and the less it degrades over distance. PE has a significantly lower $D_k$ (approx 2.2-2.3) compared to PVC (3.5-8.0), making it the mandatory choice for data cables. In the world of power transmission, High-Density Polyethylene (HDPE) offers unmatched abrasion resistance and moisture protection for cable sheathing.

However, you cannot simply load PE pellets into a machine designed for PVC and expect quality results.

The primary difference between a PVC and a PE Extrusion Line lies in the thermodynamics of the screw and the cooling process. PVC is amorphous and heat-sensitive; PE is crystalline and shear-sensitive. Therefore, PE Extrusion Lines require barrier screws for efficient melting and graded cooling troughs to manage significant material shrinkage.

Whether you are extruding a thick HDPE jacket for a power cable or a foamed PE insulation for a data cable, the success of your production line depends on mastering these material properties.

II. Understanding the Material: LDPE, HDPE, and the “Crystalline” Challenge

To configure a Wire Extrusion Line correctly, you must first understand what happens inside the barrel. PE comes in various densities, primarily LDPE (Low Density), LLDPE (Linear Low), and HDPE (High Density).

The Crystallinity Factor

When PE melts, it becomes an amorphous liquid. As it cools, it re-crystallizes. HDPE has a high degree of crystallinity, which leads to a specific manufacturing headache: Shrinkage.

- HDPE can shrink by 2-4% during cooling.

- If cooled too quickly, the outer surface freezes while the inner layer remains molten. As the inner layer eventually cools and shrinks, it pulls away from the conductor or creates internal voids.

The Screw Design: Barrier vs. Standard

A standard metering screw often fails to melt PE pellets uniformly at high speeds. Unmelted particles (“gels”) pass through the die, creating rough insulation.

For optimal PE extrusion, the machine must utilize a Barrier Screw (BM Type). This screw design features a secondary flight that separates the molten plastic from the solid pellets, forcing the solid bed through a tight shear gap. This guarantees 100% melt homogeneity before the material reaches the crosshead, preventing surface roughness and ensuring stable electrical properties.

Table: Operational Differences Between PVC and PE Extrusion

| Feature | PVC Extrusion | PE / HDPE Extrusion |

| Screw Type | Standard Metering (Deep flight). | Barrier Screw (BM) or Double-Wave. |

| Compression Ratio | Lower (approx 1.8:1 – 2.2:1). | Higher (approx 2.5:1 – 3.2:1). |

| Temperature Profile | Reverse Profile (Cooler at the head). | Flat or Ramp-up Profile (Hotter at the head). |

| Cooling Method | Cold Water directly. | Graded Warm Water (to prevent voids). |

| Die Design | Long Land length. | Short Land length (to reduce back pressure). |

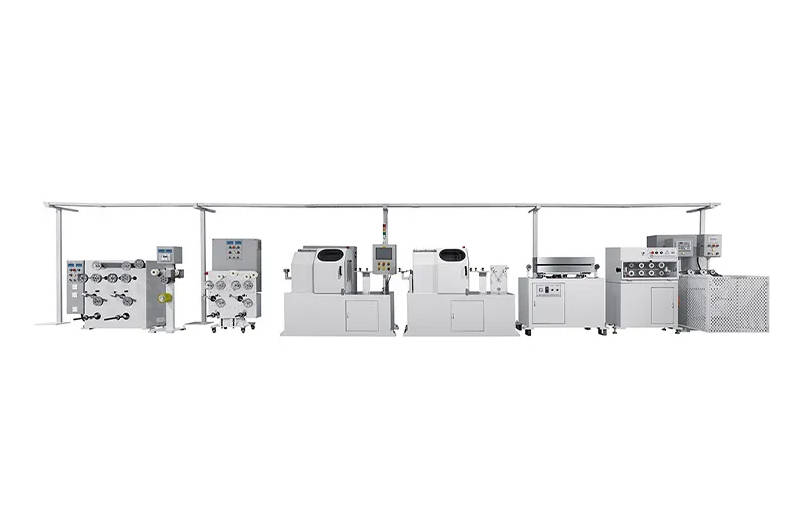

III. Configuration A: The Heavy-Duty Line (Sheathing & Low Voltage)

This configuration is the workhorse of the industry. It is used for Cable Sheathing (Jacketing) of power cables, manufacturing Aerial Bundled Cables (ABC), and producing ducting for optical fibers.

1. The High-Output Extruder

For sheathing applications, the priority is volume. Manufacturers need to cover large diameter cables with thick layers of HDPE or MDPE.

- L/D Ratio: A Length-to-Diameter ratio of 25:1 to 30:1 is standard. The longer barrel allows for better mixing and higher output pressure.

- The Barrel: Since black PE (loaded with Carbon Black for UV resistance) is abrasive, the barrel must be lined with a Bimetallic alloy (often Tungsten Carbide based) to resist wear. A worn barrel leads to “surging” (unstable output).

2. The “Vacuum Void” and Graded Cooling

A common defect in PE sheathing is a “loose jacket.” The plastic looks fine on the outside, but it slides loosely over the cable core. This is caused by rapid cooling shrinkage.

To solve this, professional PE Wire Extrusion Lines employ a Graded Cooling System:

- Section 1 (The Hot Zone): The first 2-5 meters of the cooling trough use Warm Water (60°C – 80°C). This keeps the outer skin of the PE flexible, allowing the entire insulation layer to shrink naturally towards the cable core as it cools.

- Section 2 (The Cold Zone): The subsequent troughs use ambient or chilled water to set the final shape.

3. Crosshead Selection

For jacketing, a Self-Centering Fixed Crosshead is often preferred over a manual one. It ensures that the heavy flow of plastic is distributed evenly around the cable core without requiring constant operator adjustment, reducing setup scrap.

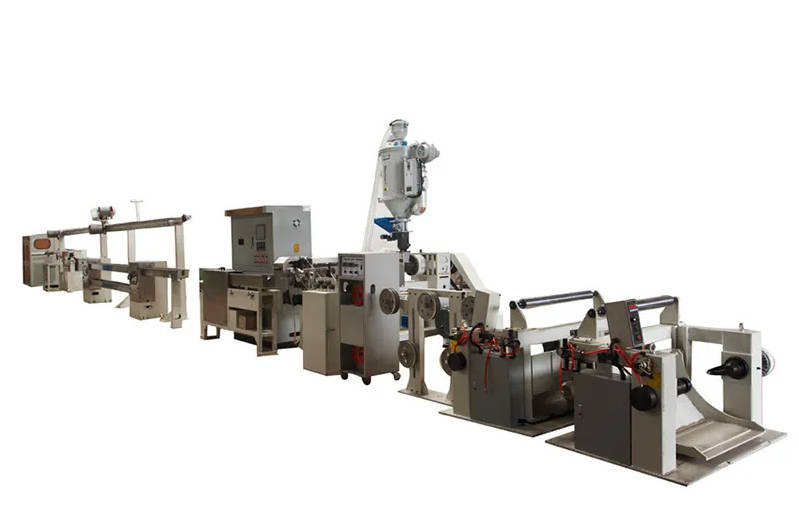

IV. Configuration B: The High-Speed Line (Data & Communication)

This is the Formula 1 of extrusion. Used for manufacturing LAN Cables (Cat 5e, 6, 7), Mini-Coaxial cables, and USB4 high-speed data wires. The goal here is not just covering the wire, but modifying the plastic’s atomic structure through Physical Foaming.

1. The Game Changer: Physical Foaming (Gas Injection)

Solid PE has a dielectric constant of about 2.3. To achieve the transmission speeds required for 5G or 40Gbps data, this is too high. Manufacturers need to lower it to around 1.5 – 1.7.

Physical Foaming Extrusion involves injecting high-pressure Nitrogen gas directly into the molten PE inside the extruder barrel. When the plastic exits the die, the gas expands, creating millions of microscopic bubbles. Since gas has a dielectric constant of 1.0, this “Foamed PE” allows signals to travel significantly faster and with less loss.

2. Skin-Foam-Skin Technology

High-end PE lines use a Co-Extrusion process to create a three-layer “sandwich” structure, known as Skin-Foam-Skin:

- Inner Skin (Solid PE): A very thin layer that adheres perfectly to the copper conductor, preventing oxidation and ensuring stability.

- Foam Layer (Gas Injected PE): The thick middle layer (60-70% expansion) that provides the electrical speed.

- Outer Skin (Solid PE): A thin colored layer that provides mechanical strength and color coding, preventing the foam from being crushed.

3. The Machinery Requirements

Producing Skin-Foam-Skin cable requires a specialized setup:

- Primary Extruder: A long (L/D 30:1 or 34:1) extruder equipped with a Gas Injection Unit. The screw has a special mixing zone to disperse the nitrogen gas without creating large bubbles.

- Auxiliary Extruders: Two smaller vertical extruders to apply the inner and outer skins.

- Specialized Crosshead: A high-precision “Micro-Crosshead” that merges these three flows perfectly before they exit the die.

V. Critical Process Controls for PE Extrusion

In the world of PE extrusion, “Geometry” is everything. For data cables, a diameter variation of just ±0.005mm can cause a failure in Return Loss (RL) or Impedance.

1. Capacitance Monitoring (The Holy Grail)

For data cables, measuring the diameter is not enough. You must measure the electrical capability.

Advanced PE Extrusion Lines incorporate a “Wet Capacitance” monitor (Water Cap) located in the cooling trough. This device measures the capacitance of the cable in real-time. The machine’s PLC uses this data to automatically adjust the extruder RPM or Capstan speed.

- Why? Because foaming degree changes with temperature. The Water Cap ensures the electrical consistency of the wire, not just the physical size.

2. Pre-Heating the Conductor

PE does not like to stick to cold copper. If you extrude hot PE onto a cold wire (20°C), the plastic chills instantly at the contact point, creating a microscopic gap.

- Requirement: An Induction Pre-heater capable of heating the copper wire to 100°C – 120°C immediately before it enters the crosshead. This ensures the polymer “wets” the surface of the copper, eliminating the “loose tube” defect.

3. Concentricity Control

Because PE is often used in thin-wall applications (e.g., 0.15mm insulation thickness for some data wires), even a slight deviation in concentricity creates a weak spot.

- Tech: X-Ray Eccentricity Gauges (like Sikora or Zumbach) are standard on high-speed lines. They provide a cross-sectional view of the wire inside the machine, allowing for automatic centering if the head is motorized.

VI. Troubleshooting Common PE Extrusion Defects

Even with the best machinery, defects occur. Here is a troubleshooting guide for the most common issues faced by PE Line operators.

Defect 1: Sharkskin (Melt Fracture)

Symptoms: The surface of the wire is rough, matte, or has a texture like shark skin.

- Cause: The molten plastic is undergoing “Critical Shear Stress” at the die exit. Essentially, it’s being pushed out faster than it can flow smoothly.

- Solution:

- Raise the Die temperature (to lower viscosity).

- Use a die with a smoother entry angle.

- Check if a Fluoropolymer Process Aid (PPA) masterbatch is needed.

Defect 2: Sink Marks or Voids

Symptoms: Dents on the surface or bubbles inside the insulation (seen under a microscope).

- Cause: The insulation cooled too fast on the outside, creating a vacuum inside.

- Solution: Increase the temperature of the first cooling trough. Allow the cooling to happen more gradually from the inside out.

Defect 3: Rough Surface / Gels

Symptoms: Small hard bumps on the wire surface.

- Cause: Unmelted PE particles (Gels) or cross-linked material falling off the screw.

- Solution:

- The screw design may have insufficient mixing.

- The screen pack (filter) is broken or mesh is too coarse.

- The barrel temperatures in the compression zone are too low.

VII. Buying Guide: Selecting the Right PE Line

If you are planning to invest in a PE Wire Extrusion Line, use this checklist to ensure the specification matches your market needs.

1. Motor Efficiency & Stability

PE extrusion requires less torque than PVC but higher speed stability.

- Look for: AC Servo Motors rather than standard AC Inverters. Servo motors provide precise RPM control even at low speeds, which is crucial during ramp-up to prevent scrap.

2. Versatility vs. Specialization

- Can I run LSZH on my PE line?

Yes, usually. Both require similar compression ratios. However, LSZH is more shear-sensitive. If you plan to run both, ensure your screw is a “Low Shear” Barrier design, not an aggressive mixing screw. - Can I run PVC on my PE line?

It is not recommended. The PE screw will overheat the PVC, causing degradation. If you must, you will need to purchase a separate PVC-dedicated screw and barrel set to swap out.

3. Crosshead Technology

- For Sheathing/Jacketing: Choose a heavy-duty, fixed-centering head. It handles the high pressure and prevents leaks.

- For Insulation: Choose a lightweight, micro-adjustable head (or fixed center with X-ray feedback) to minimize eccentricity.

VIII. Conclusion

Polyethylene is the material of the future for both robust power infrastructure and high-speed data communication. However, its crystalline nature demands a respectful manufacturing approach. A PE Wire Extrusion Line is not just a plastic pusher; it is a system of thermal management, shear control, and precision engineering.

Whether you are configuring a heavy-duty line for HDPE jacketing with graded cooling troughs, or a sophisticated Skin-Foam-Skin line for Nitrogen-injected data cables, the key lies in the details: the barrier screw, the pre-heater, and the capacitance loop.

By understanding these nuances, you move beyond simple “cable making” and enter the realm of precision manufacturing—producing cables that are not only compliant but superior in performance.

Ready to Configure Your Production Line?

Don’t let shrinkage voids or unstable capacitance ruin your product launch. Contact industry experts to specify a Wire Extrusion Line tailored for PE performance—from screw geometry to the final take-up.