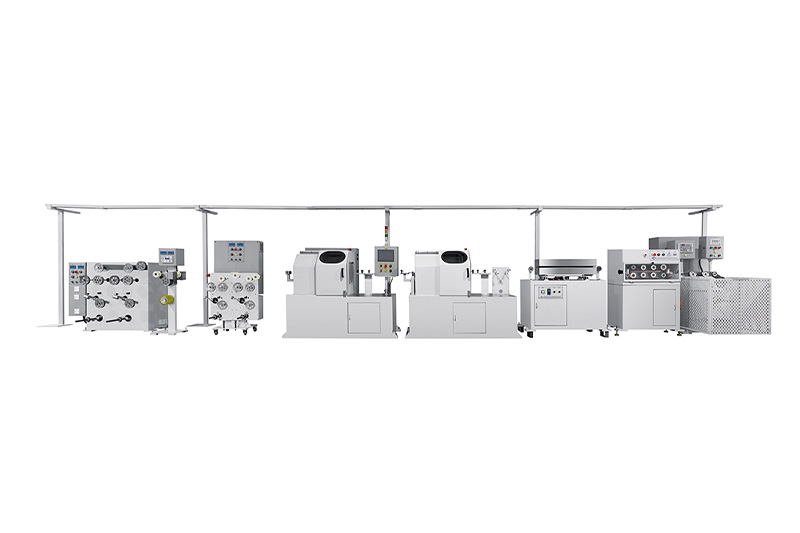

Taping Machine

Explore Our Taping Machine

Taping Machines:Almost 25 years of passion for cable industry

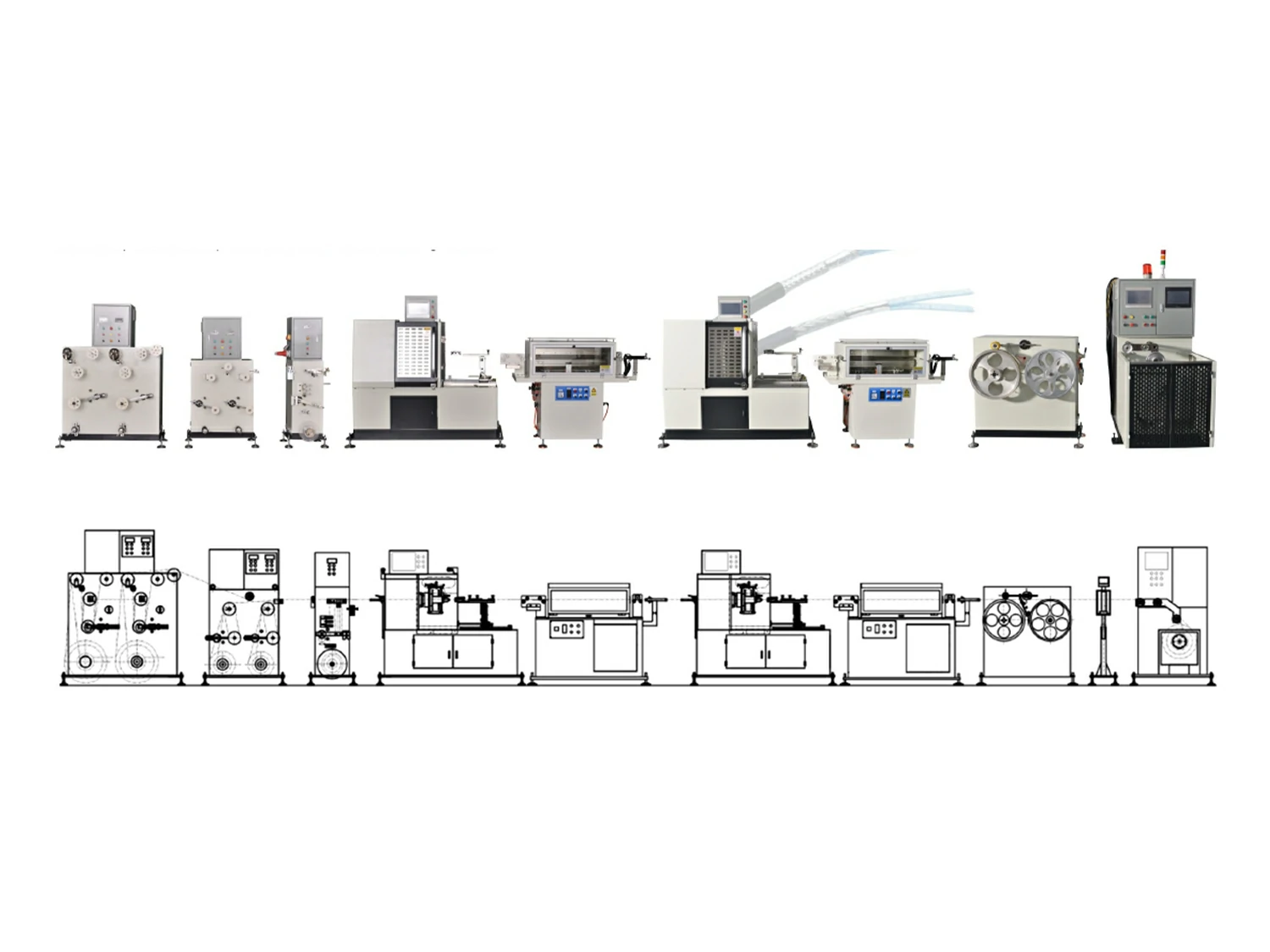

With nearly a quarter-century of expertise, Qingfeng’s horizontal taping machines are engineered to handle diverse taping materials through customizable tools. Suitable for copper foil, aluminum foil, Mylar, cotton paper, Teflon, and more, our machines support up to 5 synchronized taping units in a single line. Choose between two taping head designs: driven Kops or driven Kops with torque feedback sensors for precision control.

Major Details of Qingfeng Taping Machines

Designed for precision and efficiency, our taping machines feature integrated systems to ensure high-quality cable production:

- Pay-off & Take-up: Standard wire guides or traversing mechanisms maintain straight wire alignment.

- Straightening & Clearing: Steel rollers and brush cleaning devices prepare cables for optimal taping.

- Dynamic Dancer System: Maintains constant tape tension, critical for flat wires with high width/thickness ratios.

- Multi-Unit Synchronization: Up to 5 taping heads for complex, multi-layer applications (e.g., high-frequency data cables).

- Precision Pulling:Capstan or caterpillar systems ensure accurate linear speed and tension control.

- In-Line Testing:Laser gauges, spark testers (up to 10KV), and Vision Systems for real-time dimensional and insulation checks.

- Pre-Heating & Cooling:High-frequency induction heating and recirculated cold water systems for optimal tape adhesion and cable drying.

- Compacting Units:Ensure complete layer adhesion to the conductor.

Optional Features of Qingfeng Taping Machine

- Multi-Head Configurations:Dual/triple taping heads for simultaneous layer application (e.g., HDMI, USB 3.0 cables).

- Adjustable Heating Systems: Infrared or light wave heating (up to 200°C) for improved material bonding.

- Tension & Speed Control:Automatic tension adjustment (full to empty bobbins) and taping speeds up to 3,500 RPM.

- Material Versatility:Supports niche materials like mica tape, PTFE, and polyimide for high-temperature applications.

- Bobbin Adaptability:Accommodates Φ300mm–Φ1,250mm bobbins for varying wire diameters (Φ0.5mm–Φ20mm).

Customer Taping Machine Solutions

Qingfeng excels in providing custom Taping Machine solutions, leveraging over 20 years of experience and a dedicated R&D team of 21-30 professionals. We collaborate closely with clients to understand their unique production requirements and deliver machines tailored to their specifications. Customization options include:

- Machine Configurations:Adapting machines for specific cable types, such as high-frequency data cables or fire-resistant cables.

- Specialized Features: Integrating heating systems, precise tension controls, or online testing equipment.

- Tape Material Compatibility:Supporting a variety of materials to meet industry-specific standards.

- Scalable Solutions:Designing machines for small-scale or high-volume production lines.

Our custom solutions ensure optimal performance, efficiency, and reliability, helping clients achieve their production goals. Learn more about our offerings at Qingfeng’s Product Page.

Applications of Taping Machine

- Avionics wiring for commercial aircraft and military drones

- High-reliability shielded cables for radar systems

- Lightweight, flame-retardant cables for aerospace interiors

- 5G base station antennas (mmWave cable assemblies)

- Data center backplane cables (400G/800G optical transceivers)

- Coaxial cables for broadcast and satellite communications

- Surgical robot cables (sterilizable PTFE tapes)

- Implantable device leads (ultra-flexible micro-coaxial cables)

- Medical imaging equipment wiring (MRI, CT scanners)

- High-voltage battery cables (600V+ EV systems)

- Autonomous driving sensor cables (LiDAR, camera wiring)

- Engine compartment wiring ( 150°C+)

- Solar panel interconnection cables (UV-resistant XLPE tapes)

- Wind turbine control cables (high-flex, 10 million bend cycles)

- Nuclear power plant instrumentation cables (flameproof designs)

- Robot arm cables (7-axis articulated machinery)

- Industrial Ethernet cables (PROFINET, EtherCAT)

- High-precision motion control cables

Advantages of Qingfeng Taping Machine

Qingfeng Taping Machines offer several advantages that make them a preferred choice for cable manufacturers:

- Cutting-Edge Technology: Equipped with servo motors, PLC controls, and precise temperature regulation for reliable performance.

- High Efficiency:Optimized designs with adjustable speeds and multiple taping heads maximize production throughput.

- Superior Quality:Features like constant tension control and online spark testing ensure consistent, high-quality output.

- Customization: Tailored solutions to meet specific client requirements, from tape materials to machine configurations.

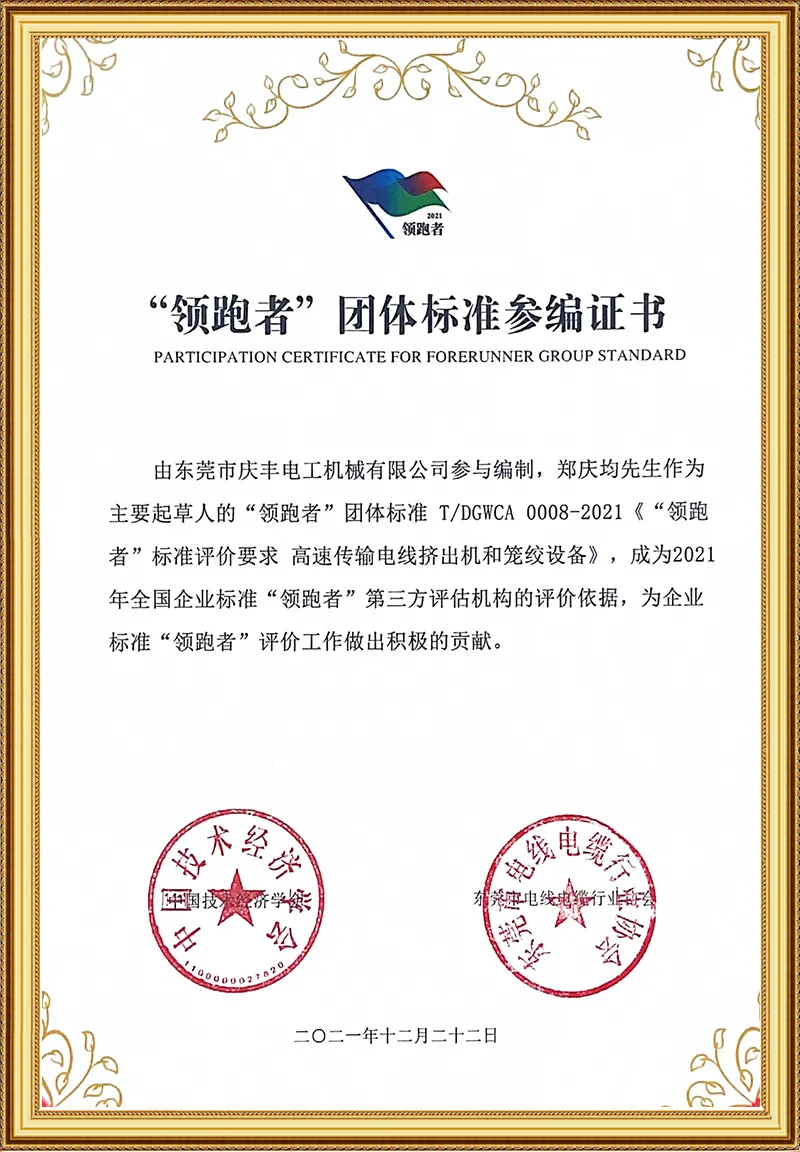

- Global Expertise: Over 20 years of experience and a presence in more than 30 countries, with partnerships with major companies like TE Connectivity.

- Comprehensive Support: Dedicated R&D team and after-sales service provide ongoing assistance to ensure optimal machine performance.

Quality Control in Taping Machine Manufacturing

Qingfeng is committed to delivering Taping Machines of the highest quality, as evidenced by our ISO 9001:2015 certification (Qingfeng Company Profile). Our rigorous quality control processes include:

- Material Selection:Using high-grade components to ensure durability and longevity.

- Precision Engineering: Employing advanced manufacturing techniques to achieve precise tolerances.

- Thorough Testing:Conducting functional tests, performance evaluations, and safety checks on every machine before delivery.

- Continuous Improvement: Incorporating customer feedback and industry advancements to enhance our products and processes.

- Regular Audits: Conducting internal and external audits to maintain compliance with international quality standards.

These measures ensure that every Qingfeng Taping Machine meets the highest standards of performance and reliability.

Why Choose Us Taping Machine

Over 600 clients worldwide trust Qingfeng for their Taping Machine needs due to our proven track record and commitment to excellence:

- Possibility to use both tape spools and pads.

- High sensitivity dancer for tape tension control.

- Load cell for checking the tape tension.

- Threshold detector for identifying speed synchronism malfunction or wire breakage.

Our partnerships with industry leaders and our export to over 30 countries underscore our reputation as a trusted manufacturer.

Frequently Asked Questions

A Taping Machine applies tapes to wires and cables for insulation, shielding, or structural support in cable manufacturing, ensuring high-quality output for various applications.

Qingfeng offers High Frequency Dual/Triple Heads Lapping And Taping Machines, Copper Wire Horizontal Single/Dual/Triple Layer Taping Machines, and Vertical Wrapping Machines.

Yes, Qingfeng specializes in custom solutions, working closely with clients to design machines tailored to their specific production needs.

Our machines support copper foil, aluminum foil, Mylar, cotton paper, transparent tape, mica tape, Teflon tape, PTFE, polyimide, and more.

Speeds vary by model, with High Frequency machines reaching up to 3500 RPM and Horizontal machines up to 2500 RPM, depending on configuration.

All machines are manufactured at our state-of-the-art facility in Dongguan, China, adhering to strict quality standards.

Our machines are used in telecommunications, power generation, aerospace, automotive, and medical device industries.

Our standard warranty is one year, with options for extended coverage upon request.

Looking For Wire and Cable Machine Manufacturer ?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.