In the rapidly advancing world of consumer electronics, the hardware landscape has shifted dramatically. Devices are becoming thinner, faster, and more powerful. From the AI-driven processors in data centers to the 5G antennas in the latest smartphones, the demand for high-frequency data transmission has never been higher. At the heart of this ecosystem lies a critical, often overlooked component: the high-speed wire connecting these systems.

To match the performance of advanced PCBs and processors, manufacturers are moving away from traditional insulation materials like PVC and PE. They are turning to Fluoropolymers, specifically FEP (Fluorinated Ethylene Propylene) and PFA. However, processing these materials requires specialized machinery. Standard extrusion lines are incapable of handling the corrosive nature and high thermal requirements of fluoropolymers.

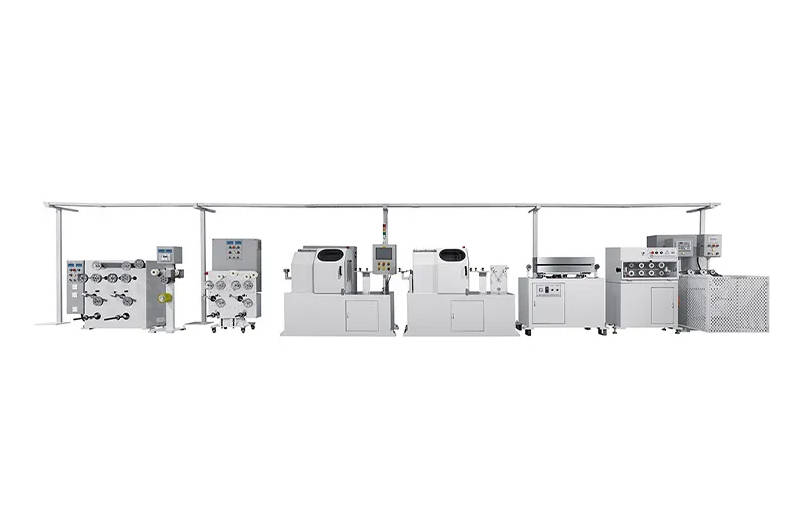

This guide details why the Teflon (FEP) Extrusion Line has become the essential investment for cable manufacturers aiming to enter the high-end supply chain for brands like Apple, Samsung, and Intel. We will explore the technical requirements, the critical hardware differences, and the production secrets to achieving zero-defect high-speed wires.

I. The Market Shift: Why High-End Electronics Demand Teflon

The consumer electronics market is currently driven by two factors: Miniaturization and Speed. The transition from USB 2.0 to USB4 (40Gbps) and Thunderbolt 4, as well as the adoption of PCIe 6.0 in servers, means that the physical properties of the wire insulation are now just as important as the copper conductor itself.

The Physics of Speed

As signal frequencies increase, the insulation material acts less like a protective jacket and more like a capacitor. If the insulation has a high Dielectric Constant ($D_k$), it absorbs the signal energy, causing attenuation (signal loss) and latency.

FEP and PFA are the “Gold Standard” for high-speed transmission because they possess the lowest Dielectric Constants of any melt-processable plastics.

Furthermore, modern PCBs in smartphones are densely packed. The wires connecting components (like the coaxial cable connecting the 5G antenna to the mainboard) must be microscopic. FEP offers exceptional dielectric strength, allowing manufacturers to extrude ultra-thin walls (down to 0.05mm) without risking electrical breakdown. This capability is what allows foldable phones and ultra-thin laptops to exist.

Comparison: Standard vs. High-Performance Insulation

| Feature | PVC (Standard) | PE (Polyethylene) | FEP (Teflon) | PFA (Teflon) |

| Dielectric Constant ($D_k$) | 3.0 – 8.0 (Poor) | 2.2 – 2.4 (Good) | 2.1 (Excellent) | 2.1 (Excellent) |

| Operating Temperature | 60°C – 105°C | 75°C – 90°C | 200°C | 260°C |

| Dissipation Factor | High (Signal Loss) | Low | Extremely Low | Extremely Low |

| Chemical Resistance | Low | Medium | Inert (Excellent) | Inert (Excellent) |

| Processing Difficulty | Easy | Medium | High (Corrosive) | High (Corrosive) |

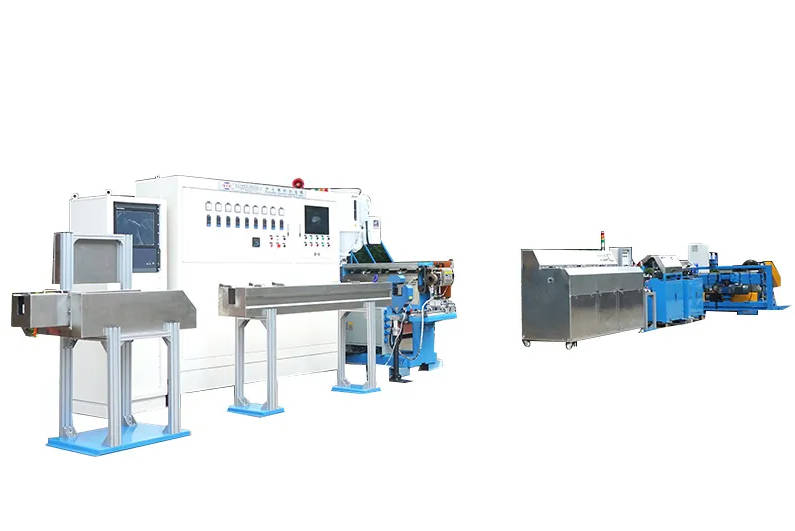

II. Critical Hardware: Why You Cannot Use a Standard Extruder

A common question from manufacturers is: “Can I just upgrade the heater bands on my PVC extruder to run FEP?”

The answer is a definitive NO. Attempting to process fluoropolymers on a standard PVC or PE machine will result in catastrophic machine failure within weeks.

1. The Corrosion Factor

When FEP or PFA is melted (typically between 350°C and 400°C), it can release trace amounts of highly corrosive fluoride gases (essentially Hydrofluoric Acid). Standard nitrided steel screws and barrels will corrode rapidly. The screw flights will pit and degrade, leading to contamination (black spots) in the insulation and unstable pressure.

To successfully manufacture Teflon wires, the Extrusion Line must use screws and barrels made from specialized high-nickel alloys, such as Hastelloy C-276 or Inconel 625. These materials are impervious to fluoride corrosion, ensuring the longevity of the machine and the purity of the wire insulation.

2. The Screw Geometry

FEP has different rheological properties (flow behavior) than Polyethylene. A standard metering screw will cause excessive shear heat, degrading the material.

- Compression Ratio: FEP screws typically require a lower compression ratio (around 3:1) compared to other materials.

- L/D Ratio: A Length-to-Diameter ratio of 24:1 or 26:1 is standard to ensure sufficient residence time for uniform melting without burning the material.

3. High-Temperature Heater Bands

Standard cast-aluminum heaters often melt or fail above 300°C. A professional Teflon Extrusion Line utilizes Cast Copper or high-performance Ceramic heater bands capable of maintaining stable temperatures up to 500°C. Crucially, these lines require high-power air cooling blowers to prevent temperature overshoot, as FEP is sensitive to overheating.

III. Key Process Controls for “Zero-Defect” Production

In the production of high-frequency cables (like HDMI 2.1 or USB-C), “good enough” is not acceptable. A variation of just a few microns in the insulation diameter can alter the cable’s Impedance (typically 50Ω or 90Ω). If the impedance fluctuates, the signal reflects back (Return Loss), and the cable fails certification.

Therefore, a top-tier FEP Extrusion Line relies on three pillars of process control:

1. Concentricity Control (>95%)

Concentricity refers to how perfectly centered the copper conductor is within the insulation. If the wire is off-center, the electrical properties become unbalanced.

- The Solution: Use of a “Fixed-Centering” or “Self-Centering” Micro-Crosshead. Unlike adjustable heads used for power cables, these high-precision heads are machined to exact tolerances.

- Monitoring: The line must include an X-Ray Diameter and Concentricity Gauge (like Zumbach or Sikora) that provides real-time feedback. If the concentricity drops below 93-95%, the system should alarm immediately.

2. Online Capacitance & Diameter Feedback

For data cables, capacitance is the critical metric. It is not enough to just measure the diameter; you must measure the electrical capability of the insulation.

- Water Capacitance Monitor: This device is installed in the cooling trough. It measures the capacitance of the wire while it is submerged.

- Closed-Loop Feedback: The extrusion line’s PLC (Programmable Logic Controller) takes data from the capacitance gauge and automatically adjusts the Capstan Speed or Extruder RPM.

- The Result: Advanced Teflon Extrusion Lines utilize a closed-loop feedback system where the capacitance monitor directly controls the extruder output. This ensures that the capacitance per meter remains constant throughout the entire reel, guaranteeing uniform signal transmission speeds.

3. Ultra-Fine Tension Control

When extruding micro-coaxial cables (e.g., AWG 40 – AWG 46), the copper conductor is thinner than a human hair. Traditional dancer arms or heavy accumulators will snap the wire or stretch it (elongation).

- Elongation Limit: Stretching the copper changes its resistance.

- Technology: High-end lines use active driven payoffs and precision servo motors with load cells measuring tension in grams, not kilograms.

IV. Common Production Challenges and Troubleshooting

Processing FEP is an art as much as a science. Operators often face specific defects. Understanding these challenges is key to selecting the right machinery features.

Challenge 1: Die Drool (Plate-Out)

Symptoms: Accumulation of material at the die exit, which eventually breaks off and sticks to the wire, causing a lump.

Cause: Incompatible additives in the FEP or improper die land length design.

Solution: Using a die with a modified exit geometry and optimizing the shear rate. High-quality extrusion lines often feature “air wipes” or nitrogen shielding at the die head to reduce oxidation and accumulation.

Challenge 2: Sharkskin (Melt Fracture)

Symptoms: The surface of the wire looks rough, like shark skin, rather than smooth and glossy.

Cause: The material is being pushed through the die too fast, creating unstable flow (exceeding critical shear stress).

Solution:

- Increase the die temperature (to improve flow).

- Reduce the line speed.

- Machine Factor: Ensure the extruder screw design is optimized for FEP to deliver a smoother melt stream.

Challenge 3: Cone Breakage (Sparking)

Symptoms: The molten cone of plastic breaks before coating the wire, or “sparks” (pinholes) are detected.

Cause: Draw Down Ratio (DDR) is too high.

Solution: FEP allows for a high Draw Down Ratio (DDR), often between 80:1 and 100:1. However, going beyond the material’s limit causes breakage. The tooling (Die and Tip) must be calculated precisely for the target wire size.

V. Specific Applications in the Consumer Electronics Ecosystem

Investing in a Teflon Extrusion Line opens the door to the most lucrative sectors of the wire industry. Here is where your machine will be applied:

1. USB4 and Thunderbolt Cables

These cables handle power (up to 240W) and data (40Gbps) simultaneously.

- Requirement: Twisted pairs insulated with FEP (often foamed FEP) to minimize delay skew.

- Machine Role: Producing the primary insulated conductors with tight tolerance on diameter (±0.003mm).

2. Micro-Coaxial Cables (MCX)

These are the internal nerves of electronic devices, connecting the motherboard to screens, cameras, and antennas.

- Structure: A central conductor, FEP insulation, a shield, and an outer jacket.

- Criticality: Used in the hinges of foldable phones and laptops. The FEP must be flexible and fatigue-resistant.

3. Medical Endoscopy Cables

While not strictly “consumer electronics,” this is a high-value adjacent market.

- Application: Cables connecting the camera at the tip of an endoscope to the monitor.

- Requirement: Biocompatibility and ability to withstand sterilization (autoclave). FEP is the perfect material, and the extrusion quality must be flawless to ensure patient safety.

4. Automotive Sensor Wiring

With the rise of autonomous driving, cars are becoming “consumer electronics on wheels.”

- Application: Cables for LiDAR, Radar, and Cameras.

- Requirement: Temperature resistance. The engine bay and sensor clusters get hot; FEP’s 200°C rating is essential here.

VI. Buying Guide: What to Look for in a Teflon Extrusion Manufacturer

If you are evaluating suppliers for a new FEP/PFA Extrusion Line, use this checklist to ensure you are buying a professional-grade machine.

1. Premium Brand Screw & Barrel (Crucial for Fluoropolymers)

Do not just ask about the material (e.g., Hastelloy/GH113); ask about the brand. Does the manufacturer use generic domestic alloys, or do they utilize top-tier global brands like USA Xaloy?

- The Gold Standard: Look for machines equipped with original Xaloy (USA) screws and barrels.

- Why It Matters: Fluoropolymers (FEP/PFA) are extremely corrosive under high heat, releasing hydrofluoric acid gas.

- Generic GH113: While common, the quality consistency varies, and it may wear out prematurely.

- Xaloy: Known for its superior proprietary bimetallic alloys, Xaloy offers unmatched resistance to corrosion and abrasion. This ensures the screw geometry remains precise for years, guaranteeing stable output and preventing black spots caused by metal degradation.

VII. Conclusion

The shift towards faster, smaller, and more robust electronics is not a temporary trend—it is the future of the industry. As PCB technologies evolve to support AI, 6G, and 8K video, the “highway” connecting these components must also evolve.

PVC and Polyethylene can no longer meet the demands of this new era. Teflon (FEP) Extrusion Lines are the bridge to the future of high-speed connectivity. They offer the chemical resistance, thermal stability, and electrical purity required to manufacture the next generation of USB4, HDMI, and micro-coaxial cables.

For cable manufacturers, the message is clear: To compete in the high-value supply chains of consumer electronics, automotive, and medical sectors, upgrading to specialized Fluoropolymer extrusion technology is not just an option—it is a necessity. By prioritizing corrosion-resistant hardware, precision tension control, and advanced online monitoring, you can position your manufacturing plant as a leader in the high-frequency era.