Who We Are?

Dongguan Qingfeng Electrical Machinery Co., Ltd., established in 2000, is a national high-tech enterprise and a national “little giant” enterprise. The company is an enterprise professionally engaged in R&D and manufacturing of communication cable equipment, new energy cable equipment, power cable equipment, optic fiber cable equipment and irradiation beam equipment. Our machines are widely used in the fields of aerospace, electric power, communication, intelligent robot, new energy vehicle, energy storage and medical equipment, etc.

With a strong technology R&D capability, the company has obtained over 100 domestic patents, 2 American patents and the title of “Patent demonstration enterprise of Guangdong province”. The company has passed IPMS certification and IS09001 international quality system certification.

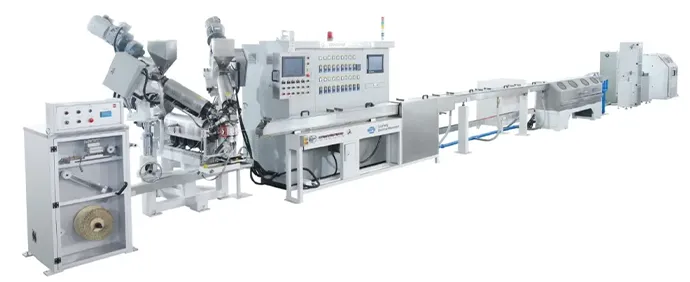

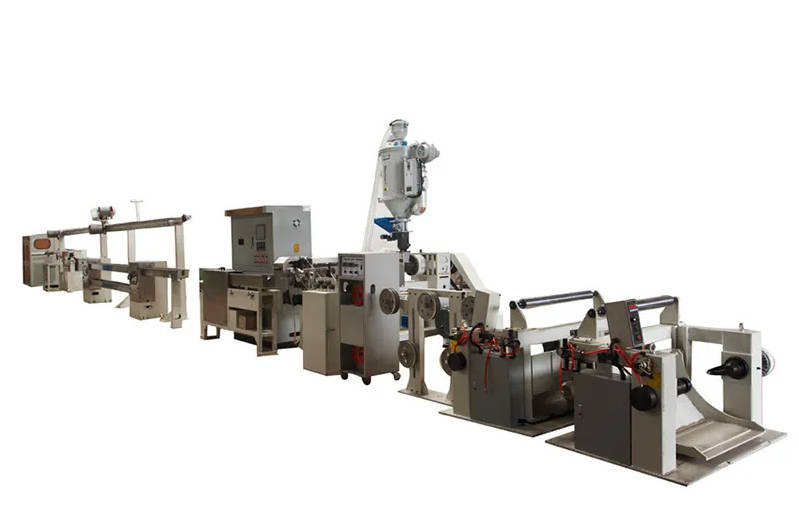

Comprehensive Cable Machinery Solutions

Explore our expertly engineered cable manufacturing machines. As a trusted manufacturer, we ensure

precision, durability, and efficiency to help your business excel and maximize ROI.

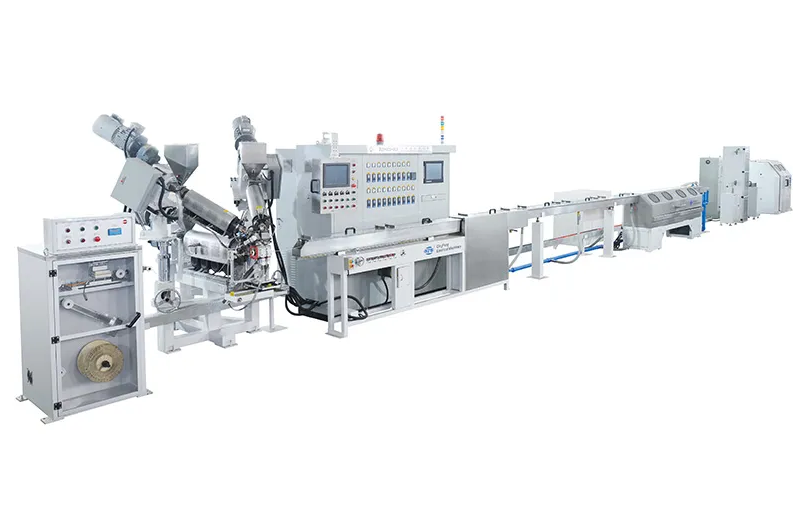

Used in high – frequency cable production: no back – twist stranding, stable electrical performance, higher efficiency and quality.

Why 600+ Partners Choose Qingfeng

Customized Products

We specialize in providing customized products tailored to your specific needs.

Continuous R&D Focus

We are committed to ongoing research and development, ensuring that our products meet the latest market demands and offer advanced features.

Prototype and Fixture Development

We have our own workshop for prototypeand fixture development and making, en-suring quick turnaround times andhiah-quality results.

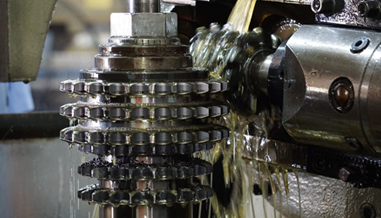

In-House Component Processing

All equipment components are processed in-house, ensuring the highest quality and performance of our products.

Comprehensive Services

We provide a one-stop service including design, manufacturing, CNC machining, surface finishing, CMM checking, and assembly.

Strategic Production Plant

With a production center in Guangdong and Jiangsu, southwest China, we can fully ensure our production capacity and future growth.

01. Design & Layout Drawings

Create machine designs and drawings as per client needs.

02.Configuration Review & Discussion

Discuss configuration to meet client needs.

03.Order Confirmation and Production Planning

Start procuring materials and planning production after order and deposit.

04.Material Cutting & Welding

Cut, shape and weld materials to ensure component integrity.

8 Steps to Custom Wire and Cable Equipment

05.Precision Machining

In - house machining ensures machine precision, reliability and stability.

06.Assembly & Electrical Setup

Engineers assemble and wire for reliable machine operation.

07.Client Commissioning

After checking out,pack the goods and arrange the delivery.

08.Equipment Packing and Delivery

After acceptance, prepare customs docs, pack, coordinate logistics and ship.

What Our Customers Are Saying

At Qingfeng Manufacturing, we understand that providing custom service tailored to each individual’s needs is essential to successful product delivery and customer satisfaction.

Recent Articles

Industry research to help our customers make informed decisions when selecting cable making machines.

Polyethylene (PE) is arguably the most versatile polymer in the wire and cable industry. Its applications range from the rugged, weather-resistant outer …

The global demand for electricity is undergoing a transformation. From the rapid urbanization requiring massive amounts of low-voltage building wires to the …

Frequently Asked Questions

To purchase our wire and cable equipment, you can contact our sales team directly through phone or email. We will guide you through the ordering process, including product selection, customization options if needed, and delivery arrangements.

The lead time varies depending on the complexity of the product and the quantity ordered. Typically, standard products have a lead time of 50 days. For custom orders, we may require additional time for design approval and testing. Please contact us for a more accurate estimate based on your specific requirements.

Each piece of our equipment comes with comprehensive installation instructions. Additionally, we offer installation support services which include remote assistance or on-site installation by our technicians, depending on your preference and location. Training sessions can also be arranged to ensure smooth operation.

We are a manufacturer with more than 17 years manufacturing experience in cable machinery,and we have production workshop and office space.

Our products come with a standard warranty period that covers manufacturing defects. The exact terms and duration vary by product. Extended warranties and service agreements are available upon request. Please consult our sales documentation for full details.

Yes, many of our machines are designed specifically for high-frequency applications, incorporating advanced technologies to minimize signal loss and interference. If you have specific requirements, we can tailor solutions to meet those needs.

Absolutely, we offer both preventive maintenance plans and emergency repair services. Our trained technicians are available to help maintain peak performance of your equipment throughout its life

Address: No36 Houhu road,Humen Town, Dongguan City,Guangdong Province,China

We are near to Shenzhen Baoan International airport within 40 mins;

We are close to Guangzhou Baiyun Airport for 1.5-2 hours.

Looking For Wire and Cable Machine Manufacturer ?

Contact us for design assistance, free quote, and expert advice today.

Your inquiry will be replied within 24 working hours, and we respect your privacy.